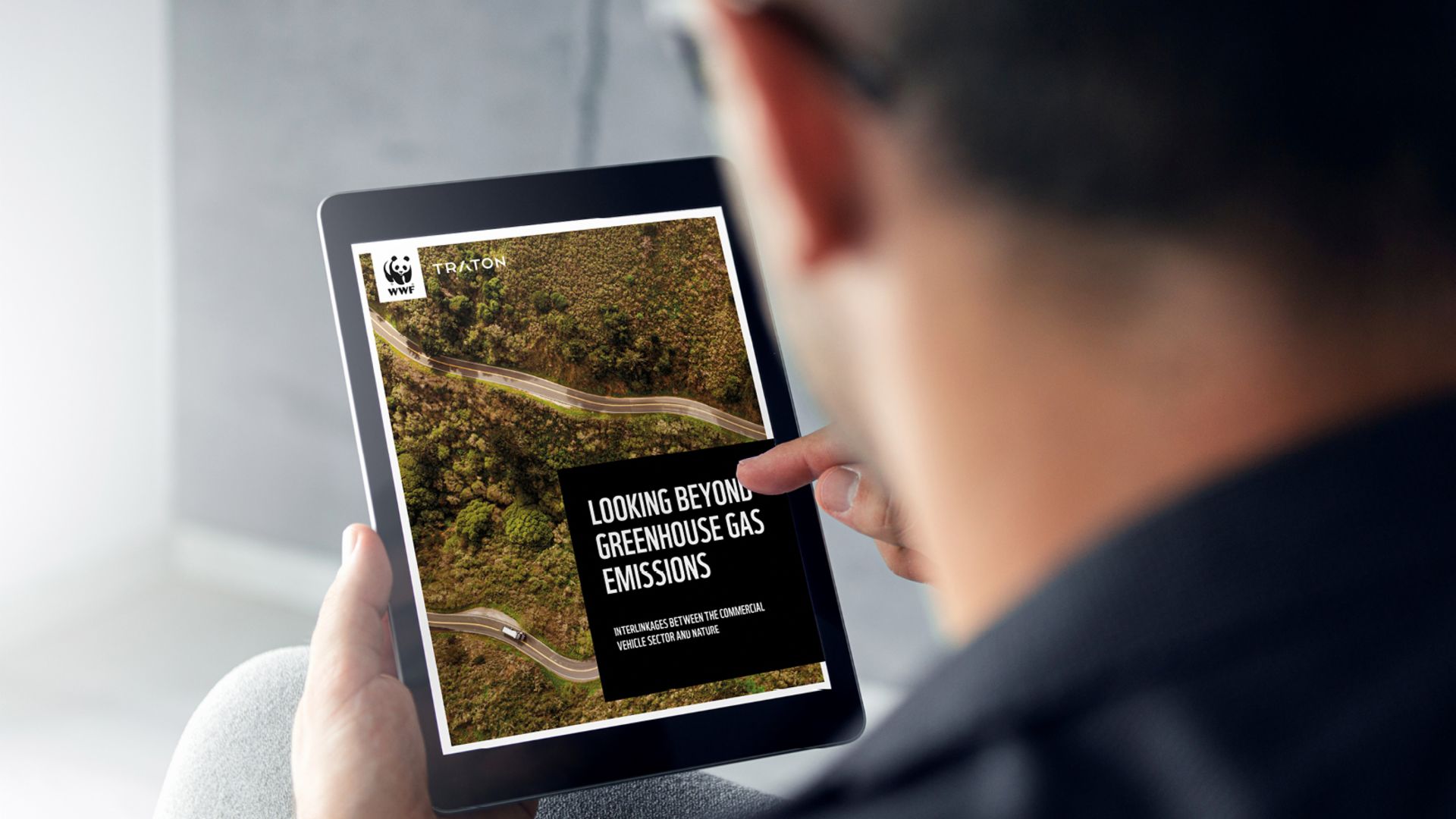

Transition to a world of sustainable transportation

With our four leading brands – Scania, MAN, International, and Volkswagen Truck & Bus – the TRATON GROUP is a transportation powerhouse and one of the world’s leading commercial vehicle manufacturers.

Together, we have unique capabilities to shape the future of transportation, empowering our brands and their customers to transform the transportation industry and benefit as a result.

TRATON’s shared purpose is “Transforming Transportation Together. For a sustainable world.”. This is what defines us as a Group. It’s not the purpose itself that makes us different, but how we execute it together and how seriously we take this commitment.

Our brands

More than the sum of its parts: Our four brands, each with its own history and strengths dating as far back as the 1800s, become one Group. We are united by shared aims and strive to create value as a single entity.

Scania is a global premium innovation leader for sustainable transportation solutions. These include trucks and buses for sophisticated transportation applications as well as numerous related service offerings.

MAN’s objective is to simplify customer business as a reliable business partner. For this purpose, MAN offers a full range of solutions, from light commercial vehicles to heavy-duty trucks.

International manufactures trucks under the International brand and buses under the IC Bus brand. The company also sells spare parts and vehicle-specific services through various partner dealerships in the USA, Canada, and Mexico.

Volkswagen Truck & Bus offers excellent value with products that are tailored to growth markets, especially in Latin America, as well as in Africa and Asia.