An example of a current initiative is the cooperation between TRATON and Hödlmayr International, a major provider of multi-modal transport solutions, with the aim of shifting more freight traffic from road to rail. The transportation of tractor units by rail is hardly possible with standard wagons due to their height. Hödlmayr has therefore decided to develop special wagons for the “High & Heavy” segment and is receiving support from TRATON. The working group led by Dr. Nikolaos Michalas, Head of TRATON GROUP Outbound, has been contributing its expertise in the delivery of commercial vehicles to the development for around a year. “With this initiative, we are underlining our commitment to sustainability and want to motivate logistics service providers to invest more in the development of rail-based solutions,” explains Fabio Castello, Chief Logistics Officer TRATON GROUP.

Transport by rail is generally relevant in countries and on routes where long distances have to be covered. This is particularly important in regions with well-developed rail networks and large geographical distances – such as in Central Europe. Germany, Austria, Poland, France and Spain have a dense rail network and support freight transport by rail in order to promote transport solutions with low CO2 impact. “Initial analyses and experience show that stable volumes in both directions are crucial for the success of the train. However, this also represents an opportunity for TRATON, as the combination of volumes from Scania and MAN in Europe allows us to map good capacity utilization for the train in a closed loop,” explains Nikolaos Michalas. “The indications are primarily in favor of a west-east connection in Europe, although other options (such as north-south) are still being investigated.” Specifically, for TRATON this means the potential to transport MAN from Niepolomice plant in Poland by rail to northern Germany, the Netherlands and England, and Scania from the plant in Zwolle in the Netherlands to Poland and south-eastern European countries.

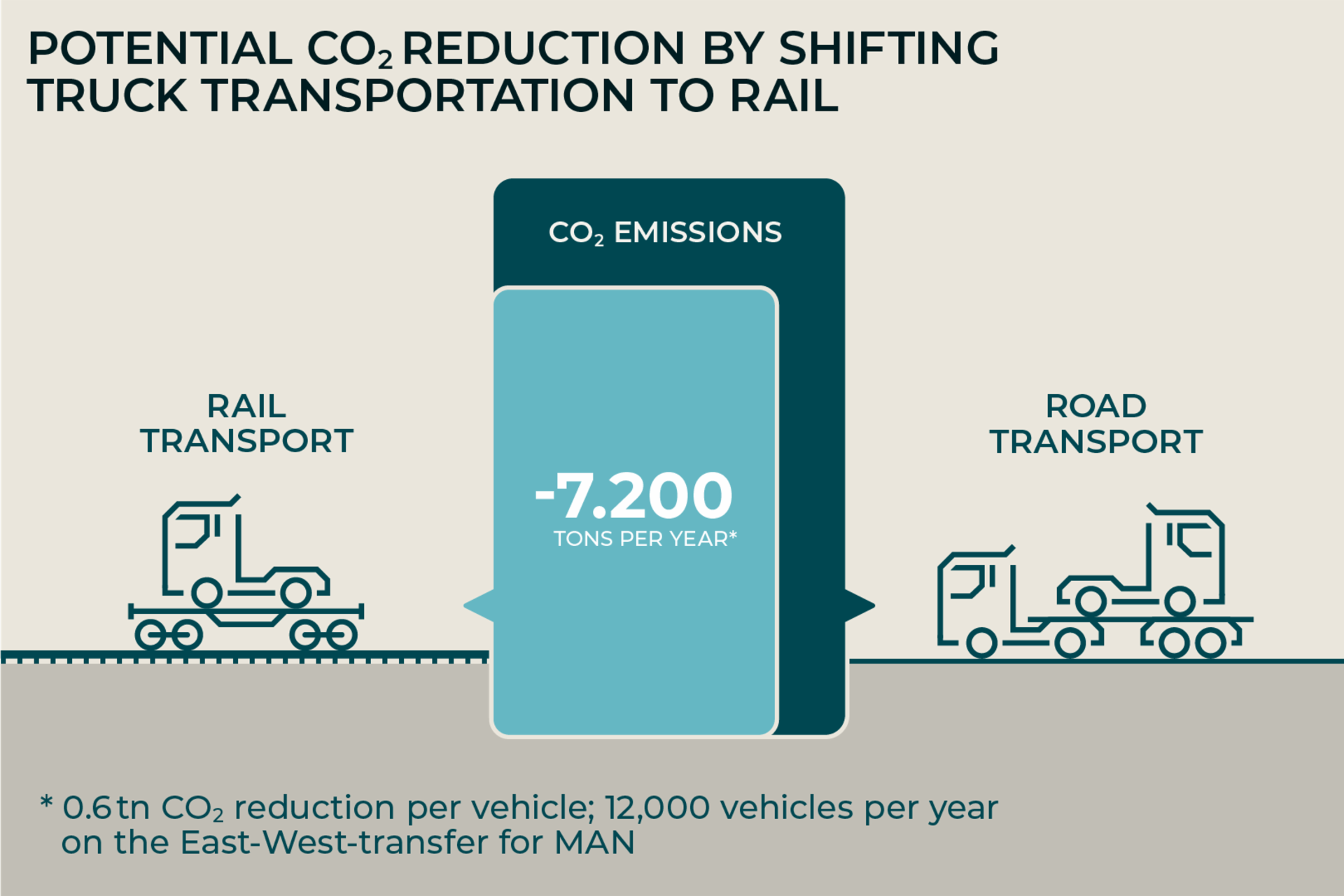

Tons of CO2 saved by shifting to rail

Hödlmayr sees huge potential for CO₂ reduction in the shift to rail: “With hub & spoke concepts, long distances are handled by rail transport, while the last mile from the vehicle logistics center to the customer is operated by truck transporters. Ideally, a block train with 14 wagons can transport 84 tractor units. With one block train per week from a loading terminal near the production plant to a compound in a geographically favorable location near the destination areas for delivery of the trucks, up to 4,000 trucks per route per year can be transported by rail. In shuttle traffic, this means up to 8,000 trucks per round trip,” calculates Michael Wöckinger, General Manager Hödlmayr High & Heavy GmbH. “Depending on the energy source used by the locomotive, rail transport delivers up to 80% emission reduction compared to diesel-powered truck traffic.”

MAN already has a train in operation for deliveries from the Niepolomice plant near Krakow. “The savings in CO₂ emissions are calculated by the current service provider at 0.6 tn per vehicle,” explains Michalas, underlining the huge potential that lies dormant here: “We are currently analyzing the scenario of the east-west connection with 12,000 vehicles per year. In this scenario alone, we are talking about a possible saving of up to 7,200 tons of CO₂ per year.”

At Hödlmayr, this initiative is part of a whole series of measures for greater sustainability. Among other things, the logistics service provider is aiming to continuously increase the proportion of vehicles in the fleet with alternative drive systems. By 2030, 10% of trucks are to be powered by renewable energy sources, and even 90% by 2040. Among other things, HVO (Hydrotreated Vegetable Oils) is already being used where possible, which can reduce greenhouse gas emissions compared to conventional diesel fuels. “The fact is, as an international vehicle logistics company, we leave behind a significant CO₂ footprint that can only be eliminated in the medium to long term. We are aware of our economic, ecological and social responsibility. That is why we have been addressing the issue of sustainability at various levels for many years,” summarizes Michael Wöckinger.

This is why Hödlmayr also uses the emissions tracking tool from Scania start-up Elain to analyze CO₂ data for high & heavy transports in Europe and Turkey. By using the Elain Advanced Tool, CO₂ emissions in logistics can be made transparent. Using data directly from the vehicle, emissions per order, recipient and carrier are visualized and make it possible to find emission hotspots, initiate improvement measures and monitor them over time. Viktoria Kindesjö, Head of Product & Sustainability at Elain, recognized the great potential for reducing the climate impact in logistics processes during the Scania trainee program and the associated rotation through various areas of the company - and subsequently founded Elain.

Electric trucks in plant logistics

The use of battery-electric trucks naturally offers an effective lever for reducing CO₂ in logistics processes. And here, too, the TRATON GROUP brands play a dual role: they offer suitable vehicles to the customers, but also use them themselves in and between the plants. The first all-electric MAN eTrucks have been operating between the German sites in Munich, Dachau, Nuremberg and Salzgitter since October 2023. Transportation to the Polish sites in Krakow and Starachowice will be added at a later date. At Scania, the plant traffic between Nykvarn and Södertälje is battery-electric, as are the internal logistics flows at the Scania plant in Oskarshamn.

Specific logistics flows at the Volkswagen Truck & Bus plant in Resende are also almost emission-free: fully electric e-delivery trucks driven by women complete around 23 round trips per day across the more than one million square kilometer plant site. Compared to its diesel predecessor, it will be able to reduce equivalent emissions by more than 90%, considering the low carbon footprint of the Brazilian electricity matrix.