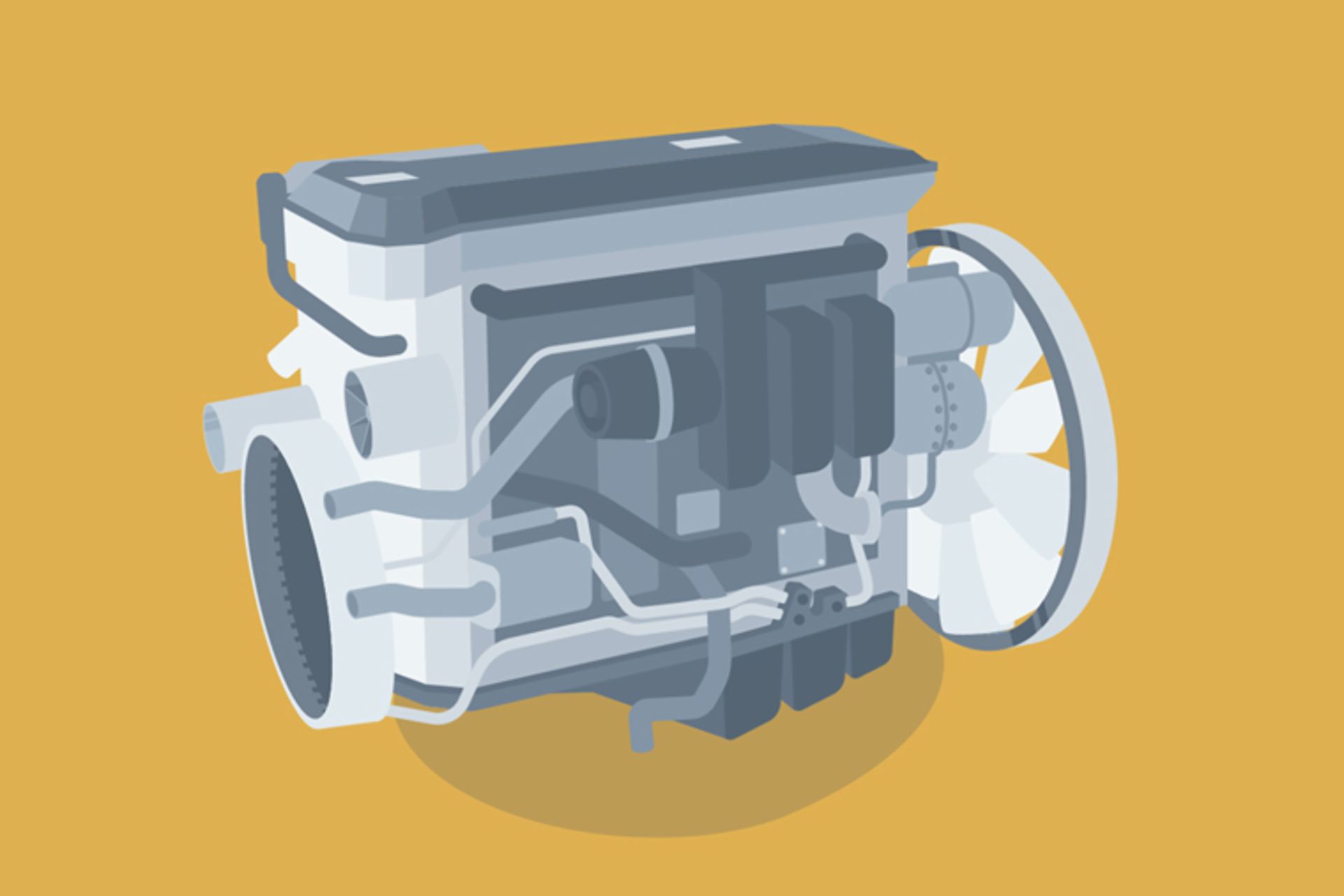

The Common Base Engine (CBE) is TRATON GROUP’s long-term engine platform. Impressive in its efficiency and low in emissions, it is further reducing TRATON’s emission footprint – and it marks a shift to cross-brand modularity for the Group. Find out more about our most advanced engine in the graphic below.

The future of the logistics industry belongs to battery-electric and autonomous vehicles. But that does not make the Common Base Engine (CBE) yesterday’s news: depending on region and area of application, it will take these innovative technologies several years to gain wide market coverage. Until that is the case, the CBE is helping to make heavy-duty commercial vehicles more cost-efficient and to reduce their emissions. At the same time, it is laying the foundation for future projects across the entire TRATON GROUP as a modular powertrain born out of collaboration between the brands.

Engine ratings from

370 HP up to 560 HP

The CBE is designed to comply with the latest emission standards for Europe, the US, Brazil and China, including approval for Hydrogenated Vegetable Oils (HVO).

With a base engine concept that delivers ca. 50% Break Thermal Efficiency (BTE) the platform provides a higher TCO value to customers.

The guiding principle is to drive commonality through the modularization principles with first deliveries being ca. 80% common.

The base engine concept has been designed with alternative fuels in mind and is positioned for the sustainable fuels of the future.

Service intervall of

150,000 km

Service life of

2,000,000 km

More than shared components

The CBE can be expanded to meet specific needs, making it suitable for use all over the world: Thanks to a modular design principle, the CBE in trucks from Scania, MAN, International, and Volkswagen Truck & Bus shares more than 80% of the same components. The engines are produced at different plants all over the world and will power the TRATON GROUP’s heavy-duty commercial vehicles in Europe, North and South America and Asia.

Södertälje/Sweden

Production in Södertälje got off to a successful start in 2022 and is now up and running. The trucks featuring the CBE are on the road under the Swedish Super label. In addition, Scania has built a new foundry in Södertälje to produce crankcases for the CBE. Cast parts from there will also supply other sites within the Group. The first truck powered by the CBE – the Scania 460 R – was honored with the Green Truck Award 2024 for its outstanding fuel economy: The Super is Scania's most advanced and high-performing combustion-engine powertrain, providing an 8% improvement in fuel consumption along with enhanced emissions control. Scania now also offers the Super 11 – a lighter, more efficient engine designed for weight-sensitive and energy-conscious high-performance transport applications.

Nuremberg/Germany

MAN has built a new production facility for the CBE at its site in Nuremberg: the ground-breaking ceremony for the 23,000 square meter hall was held in September 2021 and the first engines rolled off the production line in 2024. MAN installs the new PowerLion driveline under the name D30. The newly developed engine benefits from the combined engineering expertise of the TRATON GROUP and will replace the previously available D26 and D15 engine series in all MAN 4x2 semitrailer tractors in normal and low heights.

Huntsville/USA

In 2023, International expanded its Huntsville Powertrain Plant by 110,000 square feet and began manufacturing the CBE there under the name S13 Integrated Powertrain. This represents International’s most advanced, fuel-efficient and streamlined powertrain available in the LT®, RH™, HX® and HV™ Series. Trucks with the new powertrain are already in customer hands and on the road – and initial reactions have been overwhelmingly positive.

São Bernardo do Campo/Brazil

Scania has been producing commercial vehicles in São Bernardo do Campo, Brazil, since 1957. The site is currently undergoing further expansion. Furthermore, Scania plans to increase its engine production by 5% by December 2024, raising the capacity of its São Bernardo do Campo plant to 40,000 units per year due to rising demand abroad. The CBE will also be produced here from 2028 onward – for use in heavy-duty commercial vehicles from Volkswagen Truck & Bus.

Rugao/China

Scania’s site in Rugao is currently under construction: the new factory, which will be an integral part of the global TRATON production network in future, is being built in Jiangsu province. Production of commercial vehicles at the plant in Rugao, which is designed for an annual capacity of around 50,000 trucks, will begin in 2025.

.jpg/jcr:content/Teaser-Grafik-Tiva-Sharifi-3840x2560-V1-(1).jpg

)

.jpg/jcr:content/Teaser-Grafik-Mansoureh-3840x2560-V1-(1).jpg

)