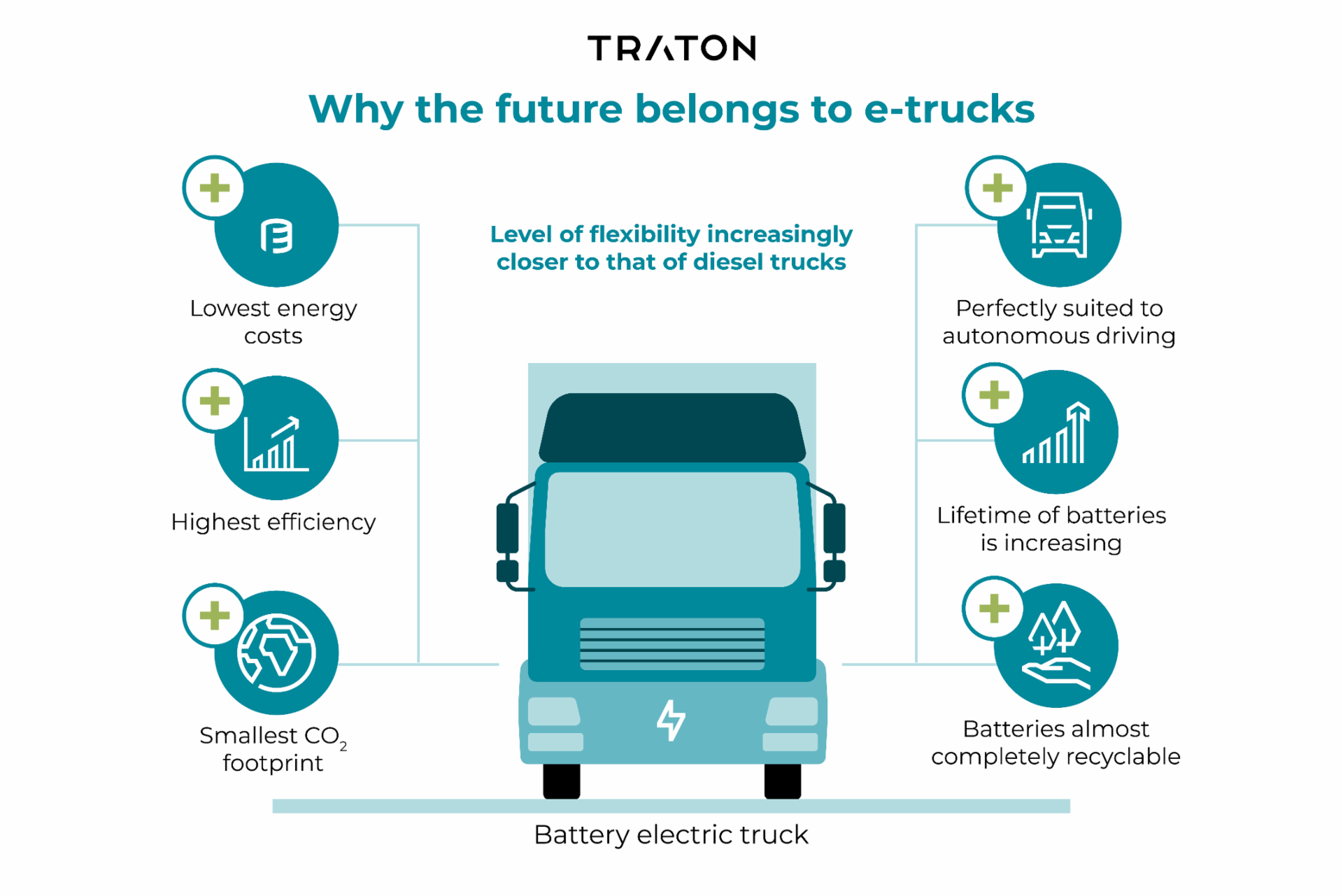

Nowadays, it’s a given that the future of freight transport on the road is electric. Because of their high levels of CO₂ emissions, a large proportion of the six million or so diesel trucks in Europe will have to be replaced by zero-emission vehicles as quickly as possible. This will benefit the environment and our inner cities, as electric motors are cleaner and quieter than diesel engines. In this context, fuel cells are often cited as being the ideal solution for powering the electric powertrain, but this is a technology that has already fallen by the wayside as far as cars are concerned. So why the enthusiasm when it comes to long-haul transport? In this case, opinions have been shaped by studies that have often been carried out on behalf of the hydrogen industry or that, due to outdated assumptions, underestimate the potential on the battery side. This is why it is time to clear up many of the misconceptions.

If you want efficiency, you need a battery

Battery electric vehicles deliver a much higher level of efficiency compared with alternatives such as hydrogen. This is a result of the complex production process. Hydrogen has to be manufactured using electrical energy and then cooled or compressed for transport before it can be used to generate electricity again in a fuel cell.

Batteries support the energy transition

"Even assuming the current electricity mix, there are few other measures that would result in such a massive reduction in CO₂ emissions with such a small investment as the introduction of fully electric trucks."Andreas Kammel

This advantage of batteries also has a positive impact on the construction of power generation facilities. Because of the greater energy efficiency of batteries, the electricity from one wind farm could power three times as many battery electric trucks as their hydrogen equivalents. Even with the volatilities of renewable energy production, this imbalance cannot be compensated. Far fewer solar and wind farms will have to be built to supply battery electric trucks, because most of them will be charging at the times of day when there is already a relative surplus of electricity, in other words, in the afternoon and at night.

On particularly windy or sunny days, they could even support the energy transition by using the excess energy for charging. This would relieve the strain on the electricity grid and allow the energy to be sold instead of being exported laboriously. In addition, the emissions of the batteries can be compensated for in only a few months and soon it will be possible to recycle at least 90% of the valuable raw materials that the batteries contain, which will improve their carbon footprint even further. From an overall perspective, battery technology is more environmentally friendly than fuel cells and also saves taxpayers’ money. “Even with the existing energy mix, there are very few other measures that would result in such a significant reduction in CO₂ emissions with such a small investment as the introduction of battery electric trucks,” says Andreas Kammel, responsible for the strategy for alternative powertrains and autonomous driving at the TRATON GROUP.

Shortages of green hydrogen

Hydrogen will nonetheless play an important role in the future. In industries where decarbonization will be difficult, such as steel production, it can make a major contribution to achieving sustainability. In the transport sector, fuel cell vehicles can also be competitive in uses cases with occasional irregular long-distance requirements, where the batteries cannot be charged quickly enough in the brief breaks or in regions where the charging infrastructure is not well developed. The use of hydrogen trucks may also be worthwhile in areas where green hydrogen is available at lower cost, such as in the vicinity of the North Sea wind farms or the ports where hydrogen is imported.

However, for the majority of applications in the transport sector, especially those with regular, intensive use, as is common in trucking, batteries are the better choice. This is partly due to the limited availability of green hydrogen. Green hydrogen, contrary to gray hydrogen, is produced using clean electricity. This means there are no carbon emission byproducts such as carbon dioxide formed during its production. However, green hydrogen is not yet being produced in sufficient quantities, and this situation is unlikely to improve significantly over the upcoming years. The demand from industry applications alone will exceed the entire local production capacity of green hydrogen currently planned for 2030. This means that fuel cell trucks would have to compete for the limited supply of green hydrogen with certain industries that cannot be decarbonized in other ways. By contrast, battery electric trucks can use the existing energy grid and benefit from the increasing expansion of the charging infrastructure.

Thanks to significantly cheaper energy prices, batteries are also more cost-effective on long-haul routes

The decisive factor in this discussion for haulage companies is the current energy price. Over the lifetime of a truck, the cost of fuel will be many times higher than the purchase price. According to some optimistic studies, for example, it will be possible to produce green hydrogen in hybrid solar and wind power plants in North Africa for €1 to €2 per kilogram and then to pump it to central Europe in pipelines. However, even under these ideal conditions, the transport and conversion costs would have to be added to the manufacturing costs, together with those – including margins – of the filling stations. This would result in a price for consumers of at least €3 to €4.

In the long term, charges and taxes of the kind that currently apply to diesel and electricity would probably also be added. “Compared to hydrogen, commercially generated electricity is significantly cheaper in almost all use cases,” says Andreas Kammel. This is most noticeable in long-haul transport when focusing on volume-sensitive freight load, but even for many weight-sensitive haulage. “Because trucks are used so intensively, cost parity between the two alternatives will only be reached if the hydrogen price at the filling station falls to around €3 per kilo or less, which is a highly ambitious target, at least as an EU average.”

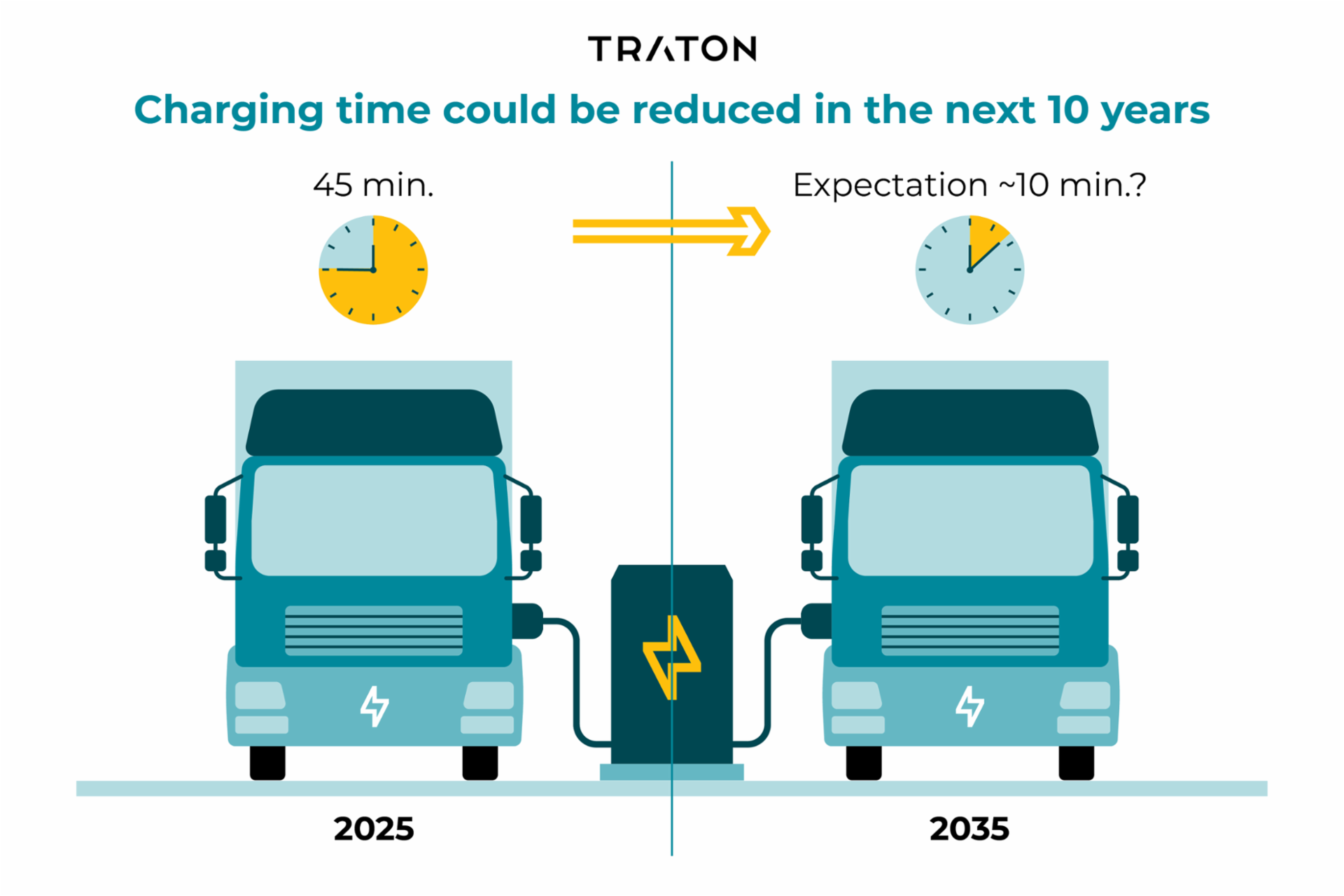

The charging time is not a problem

One of the main arguments against battery electric trucks is that the charging time is too long for the busy schedules of haulage companies. While a hydrogen truck can be filled in 10 minutes, charging a fully electric truck currently takes one to two hours. However, by 2025, this time should have fallen to only 45 minutes. “Long-haul drivers in Europe have to take a mandatory rest break of 45 minutes after four and a half hours of driving time,” says Kammel. “Provided that the necessary infrastructure exists, the battery of an electric truck can be charged during this break without wasting the driver’s time while still charging slow enough to not be putting significant strain on the battery.”

But what will happen with autonomous driving in the future? In this scenario too, hydrogen trucks appear to have the advantage because of their faster filling times, at least at first glance. However, this is a misconception, because in self-driving trucks on level 4 or above, there is no driver behind the wheel, which means that no labor costs are incurred during charging times and the costs of the downtime while charging are therefore very low. It may be the case that a pure electric truck covers a slightly shorter distance over the years than a hydrogen truck, but it is also subject to less wear, which results in a longer service life and lower depreciation.

It is clear that automated driving does not bring any advantages for fuel cell trucks that could compensate for their higher energy costs. In fact, the contrary is true. “As soon as there are autonomous trucks on the roads, the costs associated with standing still will become almost irrelevant,” says Andreas Kammel. “At the same time, energy cost and overhead will become more important because the vehicles will be used even more intensively and can be designed for a longer service life.”

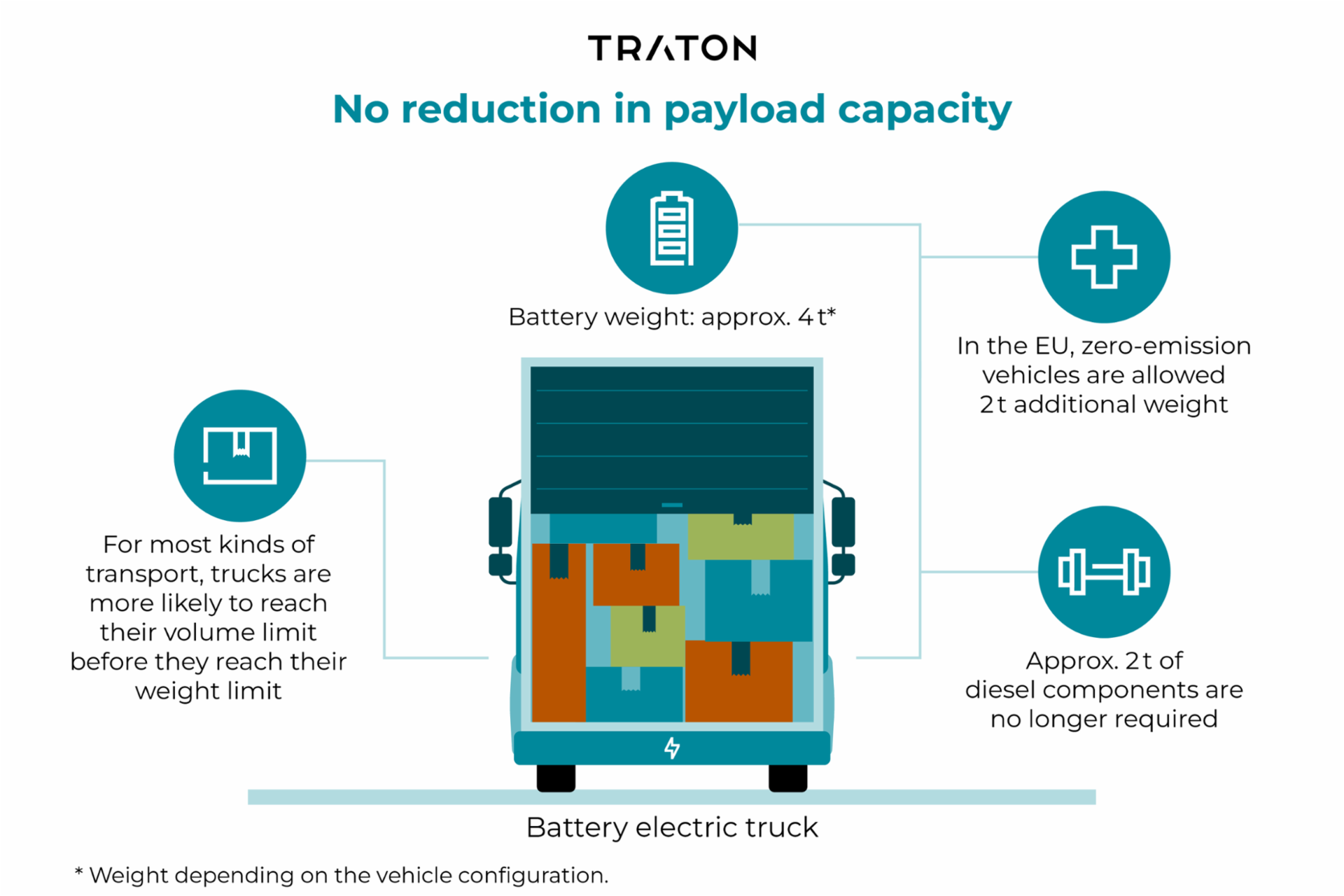

Battery electric trucks offer a lower payload

Another argument that is often heard in the discussion about zero-emission powertrains is that batteries, which currently weigh around four metric tons, are too heavy. It is true that the drive systems of hydrogen trucks are significantly lighter and that even a diesel powertrain at two metric tons weighs only half as much as that of a battery electric truck. However, the EU has increased the gross vehicle weight for trucks with zero-emission drives by two metric tons. As a result, the reductions in the payload for pure electric trucks compared to diesel truck will be small to non-existent, provided that they have the right axle configuration.

In addition, many trucks are sold in non-weight-constrained use cases like volume cargo or general cargo. For example, a truck that mainly transports e-commerce parcels is likely to reach its volume threshold before its weight limit, because a large proportion of its cargo consists of lightweight packaging materials. In the future, it will also be possible to further increase the energy density of battery packs.

The future belongs to pure electric trucks

"Electric trucks are the main solution not only for the 2020s, but even more so for the 2030s and beyond."Andreas Kammel

In summary: fully electric trucks are the most effective solution for road transport in terms of energy efficiency, energy price, and energy availability. This is particularly true in the case of regular, intensive use on long-haul routes. Even if hydrogen were to be widely available and could be imported cheaply, the overall picture would not change drastically. In fact, from the overall system perspective, this would also result in the price of electricity falling via reconversion in times of high electricity demand. At the same time, the ongoing improvements in charging times and payloads will further reduce the existing convenience disadvantages of fully electric trucks. In addition, battery technology is becoming increasingly widely used. For example, more and more cities around the world are investing in electric buses, and the resulting expertise will benefit the development of electric trucks. Furthermore, as the cost benefits increase as battery technology matures and the energy throughput and utilization levels of the charging infrastructure rise, the convenience of battery trucks comes closer to that of their hydrogen equivalents. For some specific applications, however, hydrogen will be a complementary solution, with the exception of some niche applications. “In light of these advantages, fully electric trucks are the main solution not only for the 2020s, but even more so for the 2030s and beyond,” says Andreas Kammel.