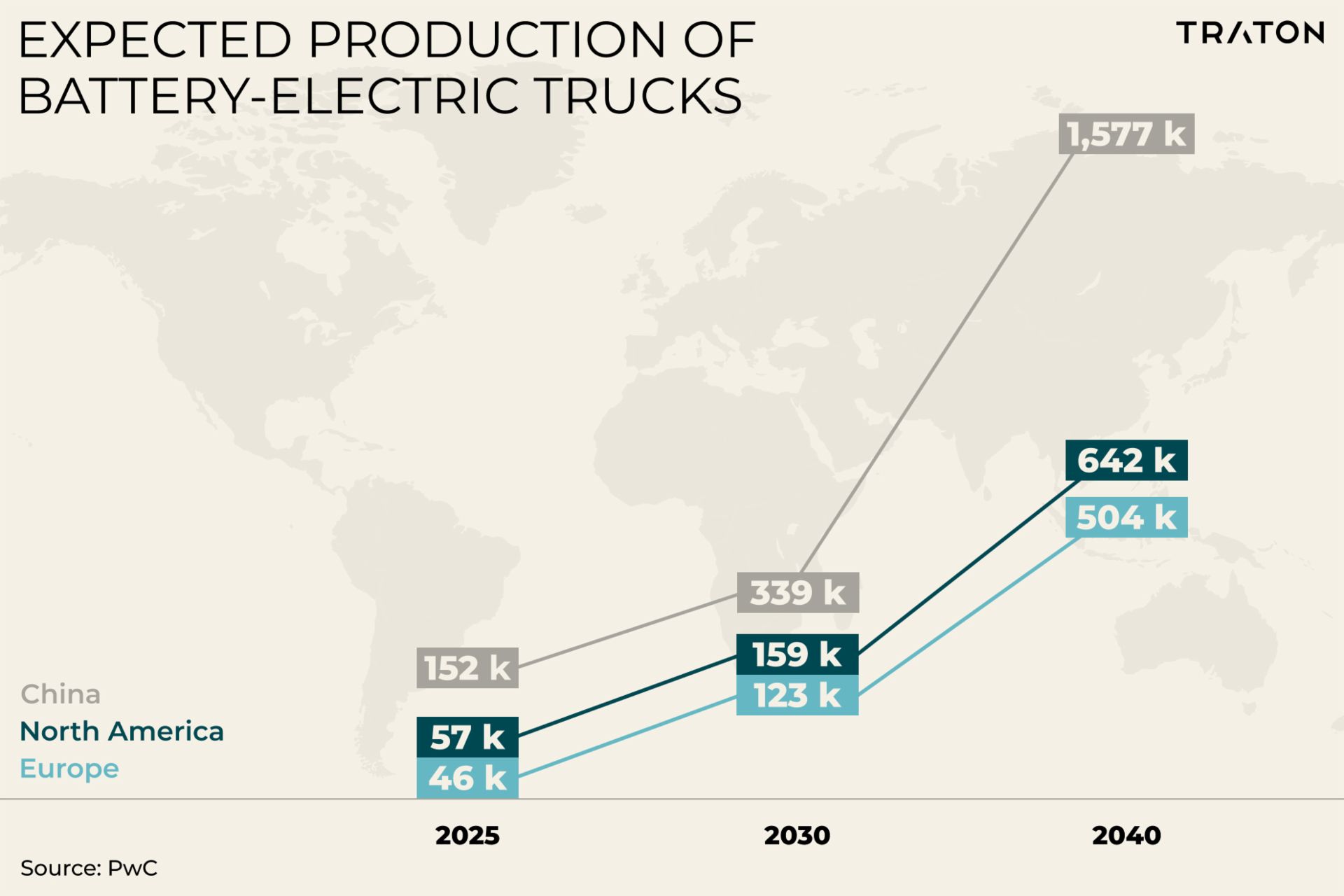

PepsiCo, DB Schenker and DHL are increasingly recognizing the importance of using battery-electric commercial vehicles (BEVs). And with good reason, given that BEVs are renowned for their reliability and efficiency. According to the “Truck Study 2024” by the business consultancy Strategy& part of Price Waterhouse Coopers (PwC), around one in five trucks in Europe, North America and China is expected to be a BEV by 2030; by 2040, the share of BEVs among new registrations will rise to more than 90%. This development will be driven by stricter legal requirements, advancements in battery technology, the establishment of widespread high-performance charging infrastructure, and a focus on reducing total cost of ownership (TCO). PwC predicts that from 2025 onwards, battery-electric commercial vehicles will generate higher economic returns than their combustion engine counterparts. Furthermore, at megawatt charging stations, battery electric trucks can accumulate enough charge in 30 minutes to travel 400 kilometers, thereby improving their economic feasibility and operational efficiency.

Further information

-

An electric truck battery is designed to meet the demands of heavy-duty transport and serves as a CO₂-friendly alternative to conventional diesel vehicles. It compprises multiple cells that store electrical energy, with large truck batteries boasting capacities of several hundred kilowatt hours (kWh) to ensure sufficient power for long distances and heavy loads. This stored energy powers an electric motor that drives the wheels. One of the key advantages of electric motors is their ability to deliver high torque even at low speeds, which is particularly beneficial for heavy trucks. This type of drivetrain is significantly more efficient than that of a conventional combustion engine, as it loses less energy as waste heat and the electric motor has fewer moving parts, reducing maintenance requirements.