1. Battery electric trucks have a large carbon footprint

At first glance, pure battery electric trucks have a supposedly heavy CO₂ backpack, mainly due to the production of the battery. Nevertheless, the carbon footprint of battery electric trucks is significantly better than that of diesel trucks and fuel cell trucks. As soon as the vehicle goes into operation, the battery electric truck’s balance starts catching up within a very short time: its efficiency is simply unbeatable. One reason for this is that hydrogen has to be produced using electricity and then has to be cooled and compressed for transport before it can be used to generate electricity again in a fuel cell. Through intensive use, even the carbon footprint of current batteries is amortized within months. In addition, in the near future it will be possible to recycle at least 90% of the valuable raw materials in the batteries, making them much more environmentally friendly.

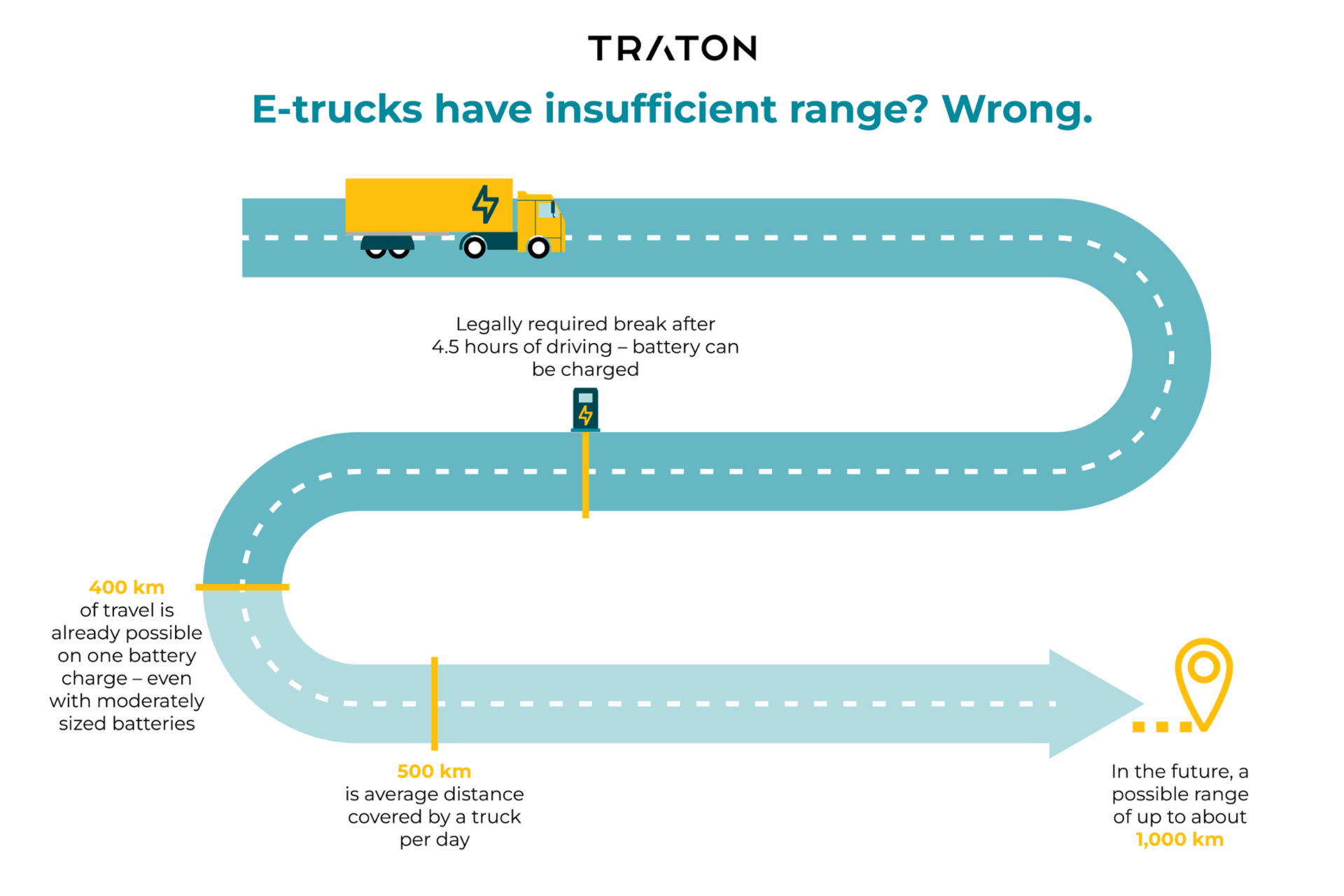

2. Battery electric trucks do not offer enough driving range for long-haul trucking

An average long-haul truck covers a distance of around 500 kilometers per day. In the near future, a realistic range from one charge for many common trucks will be approximately 400 kilometers – even under difficult environmental conditions. Yet the range will not cause issues, as long-haul drivers can charge the battery of their truck in their mandatory breaks from driving, as previously mentioned. In addition, the existing battery chemistry still offers significant potential. Within the next few years, it can be possible to travel up to 1,000 kilometers on one charge.

3. Batteries are too expensive

The price of batteries has now reached a level that, according to some studies, was not expected until 2030 – although further short-term decreases will be trickier to achieve based on an ever-increasing share of material cost. Their service life is also becoming longer and for truck-specific applications it could triple in the near future, which is even more decisive than the direct costs. Even conventional battery chemistry offers considerable room for improvement and this will have a corresponding impact on the range of future e-trucks. Maintenance and repair costs for battery electric trucks too are significantly lower. And while the advantages in the operating cost of pure e-trucks are increasing, their price level continues to fall.

4. Electricity is more expensive than other fuels

Especially in times of rapidly increasing electricity prices this argument is obvious, but in the end, the total cost of energy per ton-kilometer determines how cost-effective a powertrain is. Even taking into consideration significant future price increases, commercial electricity is much cheaper. “For this reason, if a battery is used regularly and intensively, it can pay for itself more quickly than for example a fuel cell system,” says Andreas Kammel. By comparison, in an ideal scenario, green hydrogen can be produced for just over €1 per kg in North Africa or South America. But by the time it reaches the tank of a fuel cell truck in central Europe, its price has increased to at least €3 to €4, as a result of transport, conversion costs and the margins, as well as operation of the filling station itself. Even if hydrogen could be produced more cheaply, this would not change the overall picture drastically. In fact, from the perspective of the entire system, it would effectively result in the price of electricity also falling.

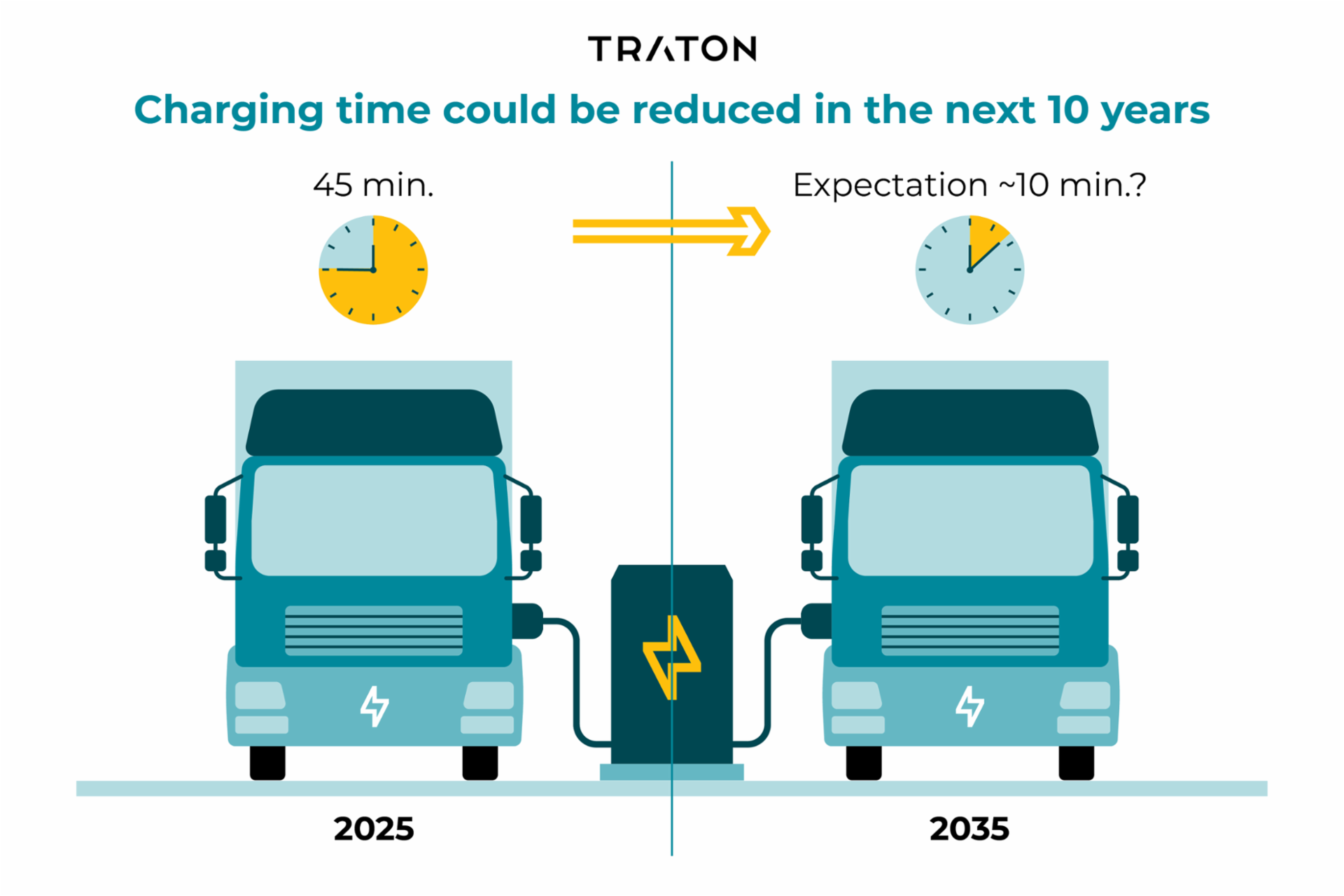

5. Charging the batteries takes too long

The charging time of a battery electric truck is currently around two hours. By 2025, this will be reduced to just 45 minutes. By contrast, a diesel or hydrogen truck can be filled in just around 10 minutes, depending on the model. Nevertheless, the battery rarely poses a problem: long-haul drivers have to take a mandatory break of 45 minutes after 4.5 hours of driving time in any case, and this is the ideal opportunity to charge the truck. In addition, battery technology is undergoing constant development. By 2035, we could be using solid-state batteries with a charging time of approximately ten minutes, which would offer the same level of convenience as filling a truck with fuel.

6. There will soon be plenty of alternative fuels available for use in trucks

More and more studies suggest that demand for alternative fuels in Europe will exceed supply for years to come. It is already becoming apparent that the demand from industry applications alone will exceed the entire local production capacity of green hydrogen currently planned for 2030. Therefore, it is quite possible that industry and the hydrogen mobility sector will find themselves in competition. Particularly as customers from carbon-intensive industries that cannot use electricity directly and urgently need hydrogen in the future will be able to buy it more cheaply because of the economies of scale. Some of these industries will also be in a position to pay more, especially if the energy costs are not quite as significant as in the case of trucks. As a result, the problem will remain, even if it were possible to import large quantities of hydrogen from abroad.

7. Power grids will collapse with the onslaught of electric trucks

Theoretically, electricity from one wind farm could power up to three times more battery electric trucks than hydrogen trucks. Even with the volatilities of renewable energy production, this imbalance cannot be compensated. Far fewer solar and wind plants than often assumed would have to be built to supply battery electric trucks, because most of them will be charging at the times of day when there is a relative surplus of electricity, specifically at noon and at night. On particularly sunny days, they could even support the energy transition by using the excess energy for charging. This would relieve the strain on the regional electricity grid and allow the energy to be used regionally instead of being exported over long distances, which causes significant strain. Additionally, electric trucks can even feed electricity back into the grid (“vehicle-to-grid”), depending on their use case.

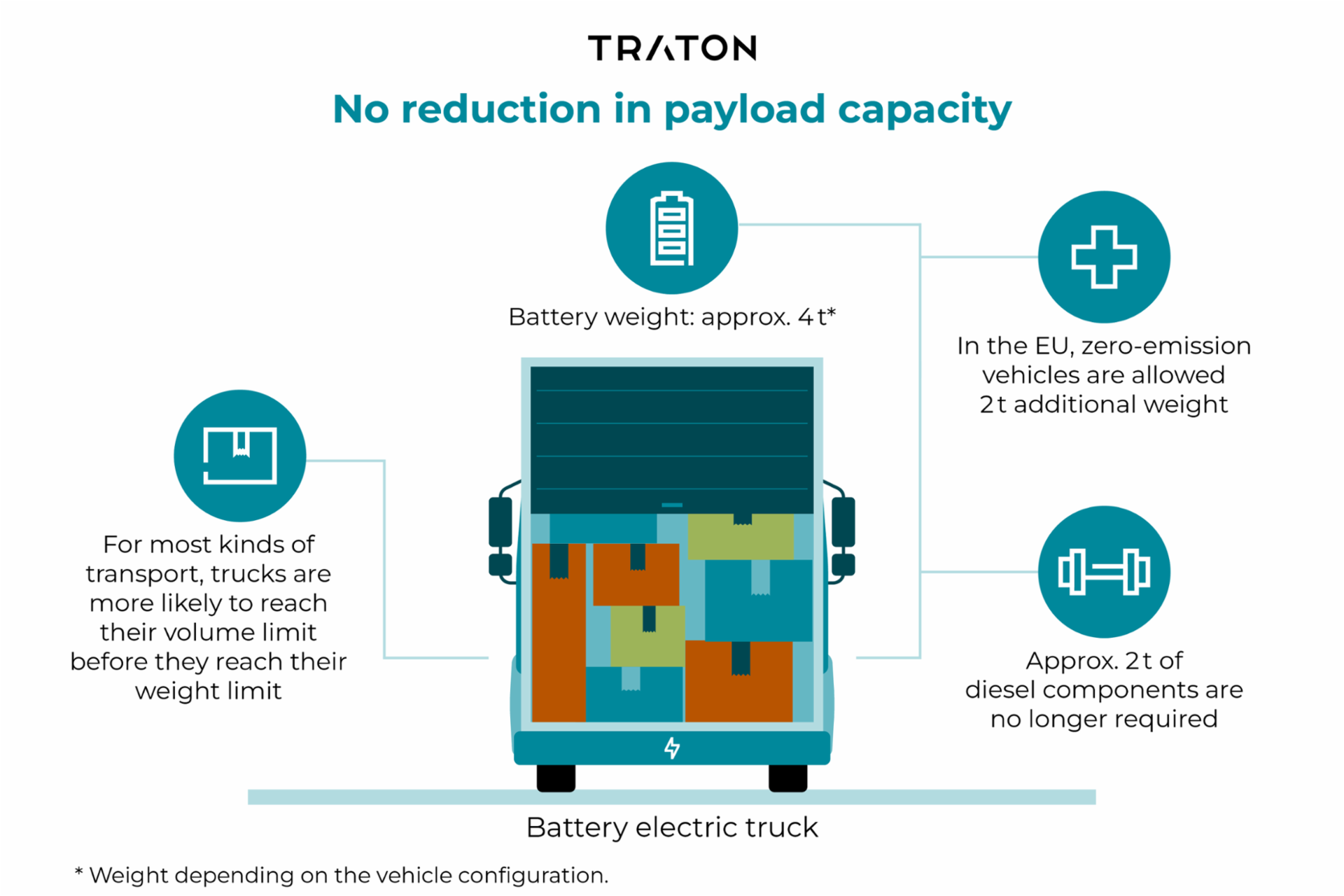

8. Battery electric trucks offer a lower payload

The battery of a pure electric long-haul truck currently, depending on the configuration, weighs around four metric tons. This is heavier than a fuel cell drive and around twice the weight of a diesel powertrain. However, because the EU permits an additional two metric tons of weight for zero-emission vehicles, the reductions in the payload will be small to non-existent, depending on axle configurations. Additionally, there is large volume of trucks sold in non-weight-constrained use cases like volume cargo or general cargo.

9. Our energy system will soon be based entirely on hydrogen

Hydrogen will definitely play an important role in the future, for example in decarbonizing the steel industry or to store energy. However, for at least the next ten years, green hydrogen will only be available in limited quantities, while the carbon footprint of conventional hydrogen, which currently dominates the market, can in some cases even be larger than that of diesel as it is produced from fossil fuels such as natural gas. “Green hydrogen will be decisive in decarbonizing a range of industries. But it will arrive too late and be too expensive to make enough of a splash in road freight to have a sizeable impact on climate change when it is needed the most,” says Andreas Kammel. In most cases it is more effective and energy-efficient to use the renewable electricity directly in battery electric trucks.

10. Batteries are unsuitable for long-distance trucking

Batteries are considered the mainstream solution in the discussion surrounding the future of cars, being both cheaper and more efficient than other zero-emission drives. However, there’s skepticism about their application in trucks. The prevailing view is that they are not up to the intensive use and the heavy loads, and also that they are too expensive to buy. Especially, as in the long-haul transport industry, where margins are slim, financial considerations often play a greater role in purchase decisions than they do on the private vehicle market. Correspondingly, this is where battery electric trucks have the advantage in particular: “They offer lower energy cost and considerably higher efficiencies than all other alternative drives,” says Andreas Kammel, responsible for alternative powertrains and autonomous driving at the TRATON GROUP. “If you already think that battery electric drives are a great solution for cars, you should definitely feel the same way about trucks.”