Climate change is the biggest challenge of our age. We need to limit global warming to well below 2 degrees Celsius and, if possible, to less than 1.5, in order to avoid causing dangerous disruption to the earth’s climate system. This is the goal set by the Paris Climate Agreement, which countries all around the world have signed. Furthermore, the 27 member states of the European Union have set themselves another ambitious goal: by 2050 Europe is to be the first climate-neutral continent.

In order to achieve this, harmful carbon dioxide (CO₂) emissions must be reduced significantly in all areas of the economy. A considerable change is needed in the transport sector, with official figures revealing that there is a lot of catching up to be done. Although CO₂ emissions in the EU have fallen by a total of 23% since 1990, emissions from road transport rose by 24% in the same period. CO₂ emissions from trucks and buses increased by the same amount. Although more-modern, less-polluting combustion engines are helping to reduce the harmful emissions from trucks, the considerable growth in the volume of delivery traffic far outweighs these benefits.

Electric trucks have several advantages over diesels

The industry has a huge responsibility to ensure that our planet is habitable for future generations. The TRATON GROUP has made a firm commitment to contributing to achieving the climate targets that have been set. One thing is clear: the freight transport sector can help to limit global warning by reducing the harmful exhaust gases that contribute to the greenhouse effect.

This means that after more than a century of dominance, diesel trucks will, sooner or later, disappear from our roads in Europe. The view that is becoming increasingly widespread throughout the industry is that battery-electric trucks are the best way of achieving a zero-emission future in the vast majority of applications, while fuel cell vehicles will provide a complementary solution for special use cases. They emit a smaller amount of harmful gases than diesel trucks, cause less noise, and are much more efficient.

Combustion engines waste more than half their energy in the form of heat just between the tank and the wheel, while by comparison electric powertrains convert around 75% of the energy – from the generation of the electricity onward – into motion*. In addition, battery-powered vehicles require less maintenance and fewer repairs than those with gasoline or diesel engines. They have fewer wear parts and some oil and filter changes are no longer needed.

*The numbers are rounded and do not include the energy recovered from regenerative braking.

A move to electric vehicles brings a significant reduction in overall costs

This means that haulage companies, and therefore also commercial vehicle manufacturers, are under not only an environmental obligation to move to electric trucks, but also an economic one. Companies that miss this opportunity will see an erosion in competitiveness over time.

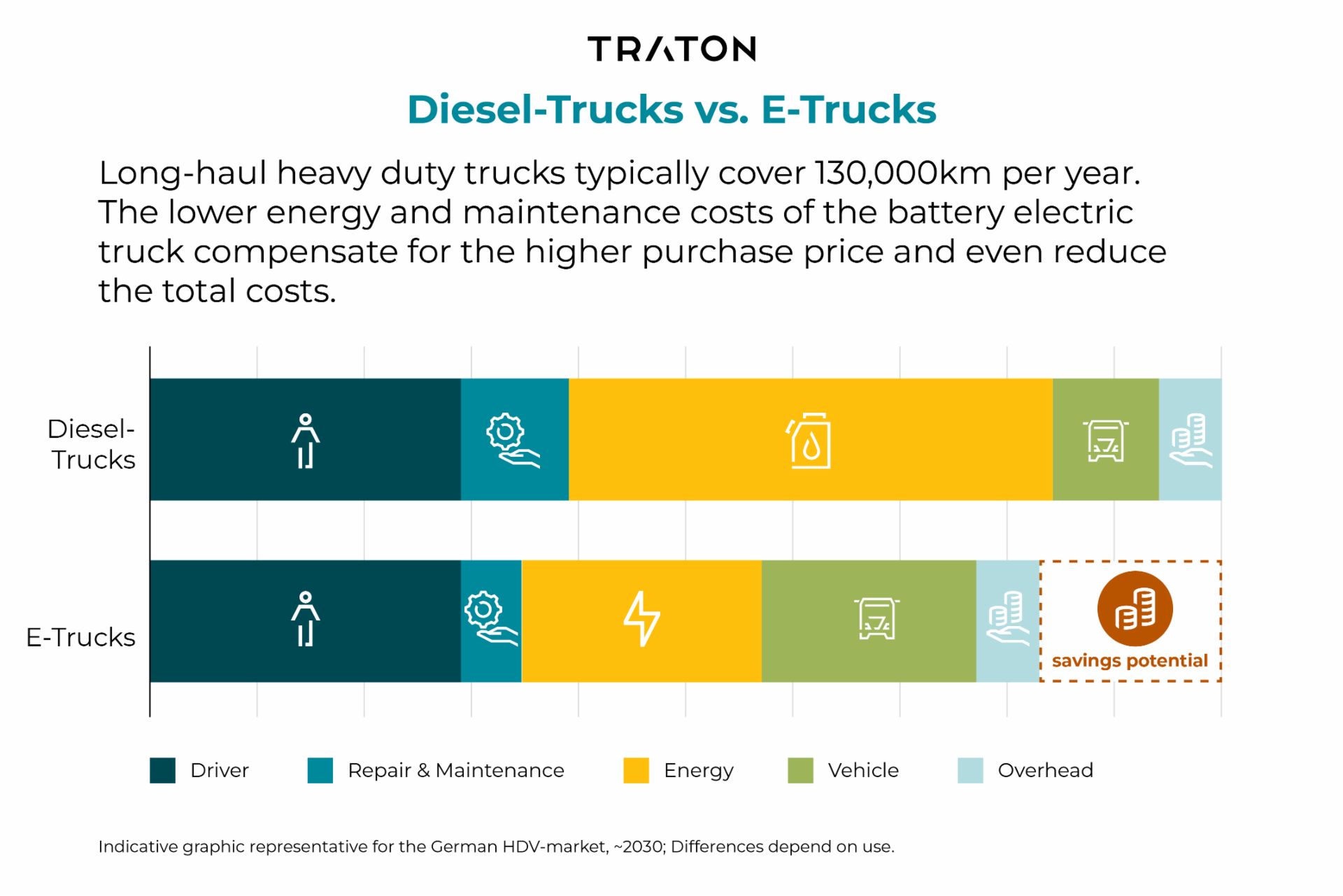

In the long term, battery electric trucks are not only more environmentally friendly, more efficient, and lower-maintenance than diesels, they are also more economical. This becomes particularly obvious in the cost-sensitive haulage sector, where margins are slim and the smallest cost benefits have a decisive impact. Although electric trucks currently have a higher purchase price than their diesel counterparts, when calculating the total cost of ownership it is important to remember that the operating costs play a predominant role. The decisive factor in the profitability of trucks is that they are investments subject to intensive use with fuel costs that significantly exceed their purchase price over their entire service life.

This is demonstrated by a sample calculation. A heavy-duty diesel truck currently costs around €100,000 to purchase. This is less than the cost of an electric truck, but over its lifetime a conventional model uses diesel fuel costing up to €500,000¹. Moving to electric trucks will lead to a huge reduction in energy costs and therefore in the total cost of ownership. This is due to the fact that in many markets commercial electricity is significantly cheaper per kilometer than diesel fuel. On average it costs half as much in Europe, for example. “This means that even large batteries will pay for themselves very quickly if the truck is subjected to intensive use,” says Catharina Modahl Nilsson, Chief Technical Officer (CTO) of the TRATON GROUP. However, establishing a sufficient megawatt charging network is one of the most fundamental requirements for the introduction of battery electric heavy-duty trucks.

E-trucks are more cost-effective than diesels – particularly for heavy-goods transport

Heavy-goods transport in particular is the most cost-effective application for electric trucks. The figures make it clear that the heavier the load and the more intensively the vehicles are used, the greater the ultimate reduction in energy costs that electric trucks can offer. Andreas Kammel, who is responsible for the TRATON GROUP’s alternative drivetrain and autonomous driving strategy, assumes that a typical heavy-duty electric truck in Europe will on average already be cheaper to acquire and operate than its diesel counterpart in 2025. “A double-digit percentage saving is possible by 2030, increasingly marginalizing diesel trucks economically and not just ecologically.”

A recently published study highlights the fact that electric trucks are already the most promising option for other applications. The prestigious Fraunhofer Institute demonstrated using the example of Germany’s second-largest retailer REWE that the company could already replace almost half of its fleet of vehicles in Berlin and the surrounding region with battery electric trucks. The report explains that “the switch would make economic sense for around 80% of the fleet.”

Europe-wide charging infrastructure needed to achieve climate goals

According to TRATON CTO Catharina Modahl Nilsson, to ensure that the long-term decarbonization of the heavy-goods industry is successful, a Europe-wide fast charging infrastructure is needed, so that trucks can be charged during drivers’ breaks. European law requires truck drivers to take a 45-minute break after four-and-a-half hours behind the wheel, which is why charging in this period will not result in any reduction in driving time. This also overturns a frequently used argument against electric mobility: the shorter range of electric vehicles.

Some battery electric trucks already have a range of 400 kilometers, and more increases are likely over the next few years as a result of developments in the technology. Battery capacity is continuing to grow, and the cost of batteries is falling much faster than was expected in the past, as some studies show. By 2030, it may well be possible to charge solid-state batteries in around ten minutes, which would be as convenient as today’s refueling processes.

“Battery electric trucks will not only be the most cost-efficient solution, but also the most efficient path towards reducing greenhouse gas emissions due to their high energy efficiency and possible rapid market ramp-up,” says Catharina Modahl Nilsson, CTO of the TRATON GROUP.

Considerable preparation needed for the charging infrastructure – the TRATON GROUP lays the foundations

Experts agree that a few years of preparation are needed before a fast charging infrastructure is available throughout Europe and that there are many challenges involved, from the regulatory framework to the booking systems. But because of high utilization rates and numerous synergies, developing the charging infrastructure could be cheaper than expected. This is largely due to the fact that many charging events are either happening slowly overnight in the depot or in the afternoon, when there is surplus electricity. “It is evident that building charging alternatives is beyond the capabilities of the truck manufacturer alone,” says Modahl Nilsson. She believes that governments are now responsible for making the necessary preparations.

Some of the largest companies in the industry are already ahead of the game. The joint venture launched by the TRATON GROUP, Daimler Truck, and Volvo Group will come into operation this year. The three manufacturers plan to invest €500 million over the next few years in installing and operating 1,700 high-performance charging stations supplying green electricity in Europe. A collaboration between competitors of this kind may seem unusual to many industry observers. “The topic is of crucial significance, and this unique cooperation will allow us to take the transformational measures that are needed to tackle climate change more quickly and more successfully,” says Christian Levin, CEO of the TRATON GROUP. This issue is so important that there is no time to lose, and TRATON has taken this on board.

¹Representative for the German HDV market; indicative - varies according to usage pattern