Battery-electric commercial vehicles (BEVs), digitalization, and more sustainable production processes have prompted a significant shift in the North American transportation market. And stakeholders must adapt to stay competitive.

How Navistar is leading the transformation

Driven by changing consumer preferences and evolving regulations, demand for sustainable transportation solutions is growing. BEV fleet operators enjoy significant carbon reductions, since battery electric vehicles can save more than 90 percent of the carbon emissions of a comparable diesel vehicle, depending on the source of electricity. This can include the upfront emissions of producing the battery due to commercial vehicles being used intensively. Improvements in battery technology and infrastructure are extending vehicle ranges, enhancing the feasibility of BEVs for commercial use. Navistar strives to lead the BEV transition in the U.S. market and is accelerating the adoption of low-emissions technologies.

The TRATON GROUP is actively contributing to the decarbonization of the transport and logistics sectors through the electrification of its product portfolio. As part of its corporate strategy, the TRATON GROUP is committed to doing its part to reduce greenhouse gas emissions throughout its value chain in line with the 1.5-degree target of the Paris Climate Agreement.

In the U.S. market, Navistar is leading the BEV transition, targeting 50% of new vehicle sales to be BEVs by 2030 and 100% by 2040. The company’s new San Antonio production plant was built to accommodate the manufacture of electric models from the outset. Since launching its first BEV models in 2021, its IC Bus brand has logged over two million all-electric miles with yellow school buses. In 2023, Navistar expanded its electric vehicle offerings by delivering its first International eMV Series BEVs to food distribution company Sysco. This marked a shift from its initial focus on electric vehicles for transporting people to those designed for delivering goods. Additionally, the company is reducing fossil fuel consumption across its operations to enhance efficiency as part of its goal to become carbon neutral by 2050.

Three key trends are reshaping the future of commercial transport in North America, with Navistar at the forefront of this transformation.

#1 – Bringing BEVs to the market at scale

A key challenge in transitioning to e-mobility is scalability. BEVs will only be sold at scale if adequate infrastructure is developed to power them. This issue is particularly pressing in the U.S. due to the limitations of existing charging networks and the complexity of varying state regulations.

Electrifying various commercial vehicle types will require public-private cooperation. Navistar recently secured a $1 million grant from the U.S. Department of Energy to develop a battery-electric snowplow, which requires substantially less power to function effectively in snowfall. This project underscores the unique hurdles of "going electric", as high energy demands and severe conditions present significant challenges.

Meanwhile, fleet operators seeking to shift to BEVs require robust support from OEMs like Navistar to navigate these complexities and ensure a successful transition.

In 2023, Navistar partnered with Quanta Services to offer a comprehensive vehicle and charging infrastructure solution for customers of its International Truck and IC Bus brands. This partnership emphasizes analyzing, forecasting, planning, and executing the electrification journey, helping customers to integrate BEVs into their fleets quickly and efficiently. Additionally, IC Bus supports dealers in educating customers about funding opportunities through the U.S. Environmental Protection Agency's Clean School Bus Program.

#2 – New digital service offerings

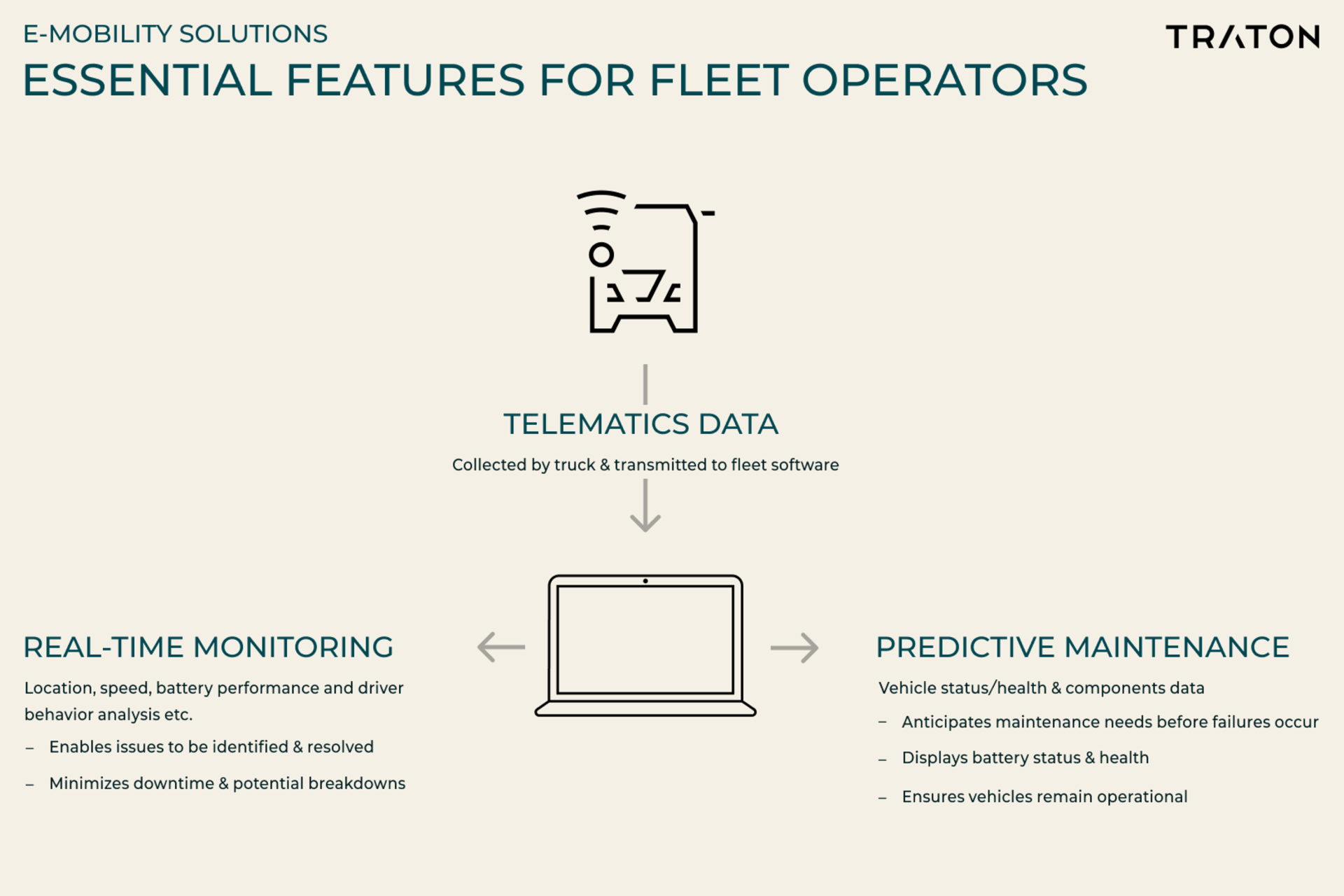

Digital services are on the rise as they allow fleet operators to optimize operations, boost efficiency, and reduce costs. Telematics has become essential for these operators. In a survey of 1,800 fleet professionals, nearly all (98%) reported using either a sourced or manufacturer-provided telematics solution across their fleet. Vehicle tracking (43%) was the primary reason for utilizing telematics, followed by managing driver performance (33%), using it for proof of service or job completion (32%), and monitoring fuel usage (30%) – especially important in challenging economic times.

Digital solutions also create major cost reduction opportunities. For example, customers using the OnCommand® Connection (OCC) tool see up to 80% fewer vehicle failures requiring a tow and an up to 30% reduction in annual repair costs.

These advanced, integrated mobility tools, coupled with analytics, enable customers to boost operational efficiency, optimize performance, and gain actionable insights to effectively address their specific needs and increase profitability.

Navistar’s advanced fleet analysis software offers predictive maintenance and telematics data to fleet managers, enabling them to assess vehicle health. This capability is especially crucial for BEVs, as it provides insights into battery charge levels, potential battery life, and other technical specifications vital for effective fleet management.

Alongside scalable BEV solutions and fleet transition support, Navistar now provides tailored digital services, marking a shift from a product- to a service-based model.

#3 – More sustainable production processes

As a responsible company, Navistar is implementing measures to reduce its energy usage, support the circular economy, and drive positive community impact. Like other TRATON GROUP brands, Navistar is committed to establishing science-based targets for validation by the global Science Based Targets initiative (SBTi), which aids companies in setting emissions targets.

In 2023, Navistar included energy efficiency as a metric for its annual performance incentives for the first time. This measures energy intensity (energy use per unit of production) at its major facilities and will account for 5% of the company’s overall incentives.

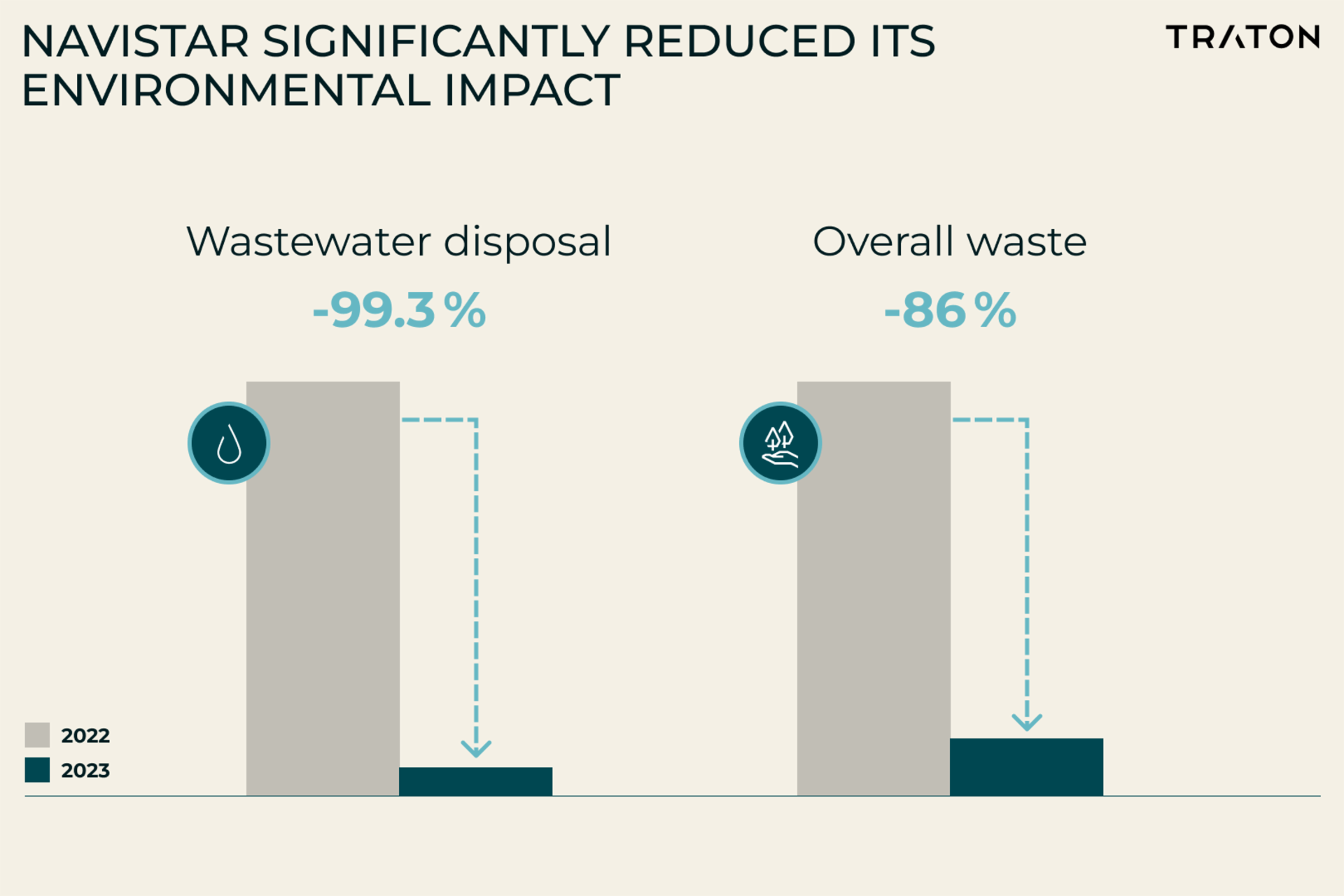

Navistar has significantly reduced its environmental impact, achieving a 99.3% reduction in annual wastewater disposal and a 97.2% saving on disposal costs at its Powertrain Plant in Huntsville, Alabama, through advanced technology. Additionally, the company donates vehicles for technician training, refurbishes IT equipment to prevent toxic metal pollution, and aims to generate 20% of its parts revenue from remanufactured components.

In 2023, Navistar recycled 86% of its waste, including materials like cardboard, paint solvents, and IT equipment. It also sells around 3,000 remanufactured parts from four central refurbishment facilities. Also, the company actively partners with community cleanups and environmental groups at its manufacturing facilities.

With ongoing innovation, strategic partnerships, and a focus on eco-friendly production processes, Navistar is poised to lead the commercial transport sector into a sustainable, electrified future.