With their futuristic appeal and relatively recent market surge, battery electric vehicles (BEVs) appear to be a modern phenomenon. However, they boast a surprisingly rich history, as the first electric carriages were introduced as early as the 1820s. For example, Scania’s first electric bus, the Scania-Vabis T31 electric bus was launched in 1940, while MAN unveiled its first-ever all-electric bus, the 750 HO-M10 E, in 1970.

These early EV developments helped pave the way for the battery-powered mobility solutions of today, where heightened awareness and concerns relating to climate change, alongside regulatory factors and technological innovations, are driving notable transitions within electrified transportation. The past decade has seen a significant hastening of the transition away from internal combustion engines (ICEs) towards electrification. The TRATON GROUP is driving this transformation across its Scania, MAN, Navistar, and Volkswagen Truck & Bus (VWTB) brands. For example, in 2022, TRATON established the charging joint venture Milence, while in September 2023, Scania celebrated the landmark inauguration of its battery assembly in Södertälje. Soon, a new generation of batteries will be introduced to herald a new era of electric transport.

The challenges facing commercial BEVs

Until recently, the bulk of attention surrounding the BEV revolution has been centered around passenger cars. However, now the focus is expanding to encompass commercial vehicles that are tasked with different demands, such as the efficient distribution of goods or people on a local level and long-haul transportation.

For commercial BEVs, various aspects must be reevaluated. For example, their batteries must provide sufficient range. Furthermore, the lifetime costs and weight implications of these vehicles must be carefully assessed, as these factors can directly impact the profitability and sustainability of their customers’ logistics and transport operations. On top of this, battery demand is rapidly increasing as the transportation industry makes substantial strides towards electrification, which requires fast-growing production capacities.

Another factor to consider is the implementation of strict emissions regulations (and incentives) that are being introduced by governments around the world to drive the transition to carbon neutrality. These include emission limits, as well as a range of safety standards and recycling guidelines, which can vary significantly from one country to another. For example, the European Union announced a number of proposals and regulations (including the new EU Batteries Regulation, effective from 18 August 2023) to achieve its legally-binding net zero goal by 2050. And in North America, politicians have worked together with major automakers to establish harmonized standards that address greenhouse gas emissions and fuel economy. By 2030, 50% of new passenger cars and light trucks must be zero-emission vehicles (ZEVs) in the United States. Similar standards are being pursued for medium- and heavy-duty vehicles with the goal of reducing nitrogen oxide (NOx) emissions.

Knowing all this, TRATON and its brands are already now making significant progress in securing strategic partnerships with battery suppliers. In April, Scania and Northvolt unveiled a jointly developed battery cell for heavy-duty BEVs. In validation tests, the lithium-ion cell demonstrated the ability to power trucks for 1.5 million kilometers – equivalent to the vehicle’s entire lifetime. Produced with fossil-free electricity in northern Sweden, the cell’s carbon footprint is approximately one-third that of comparable batteries in the industry.

Use cases for commercial BEVs: urban distribution and long-haul applications

The aspect that influences battery requirements the most are heavy-duty BEVs’ different use cases. The majority of these fall under two main categories: long-haul and urban distribution. These applications generate high annual mileage, and subsequently a product lifecycle of more than one million kilometers, while demanding highly customized specifications. However, these differences do not necessitate a completely new cell design. Instead, they require tailored mechanical and chemical optimizations to align with the distinct usage patterns and lifecycles of trucks and buses.

For a long time, there were concerns that long-haul heavy-duty commercial trucks could not be electrified due to the long distances they cover and the high costs of their batteries. This assumption has already been debunked: these vehicles cover vast distances on highways; on average, a long-haul truck travels between 130,000 and 160,000 kilometers per year (calculated at an average of 520 kilometers on 250 days per year). As a result, long-haul commercial BEVs have a higher charging cycle number and a higher energy throughput per cell compared to passenger cars, which are typically designed to travel around 240,000 kilometers over their entire lifetime.

The required extended ranges influence both the batteries and the way they are charged. In the long term, these larger vehicles will adhere to the Megawatt Charging Standard (MCS) which is currently under development to deliver high power. The MCS operates at up to one Megawatt-hour (MWh), which corresponds to a C-rate of approximately 1.2-1.4 for the size of the batteries (a C-rate of one is the current required to charge a battery in one hour). Despite the high system power, this allows for a relatively smoother charging process that places less stress on each battery cell. In contrast, the standard Combined Charging System (CCS) for passenger cars offers faster charging speeds, reaching around 350 kW, but it operates at a higher C-rate (for smaller battery systems) of approximately 3-4, due to the much smaller batteries in passenger cars. This means that while CCS provides faster charging, it may exert more stress on the battery cells compared to MCS (for larger battery systems). Ultimately, this will deliver a longer vehicle lifetime. In addition, the existing battery chemistry still offers significant potential. In the future, long-haul BEVs are expected to travel far beyond the already planned 500 kilometers on a single charge, even under difficult environmental conditions.

Use cases look very different for distribution vehicles, such as last-mile delivery trucks and city buses which primarily operate over shorter distances in urban environments and require frequent stops and starts. These vehicles typically travel 65,000 kilometers per year (calculated at around 300 kilometers per day for up to 365 days per year). They have a daily uptime of up to 20 hours (calculated at 100-500 stops per 100 kilometers). Delivery trucks can usually be charged during the day when goods are loaded and unloaded at the depot. The strategic installation of fast charging stations can ensure efficient top-ups. Last-mile delivery trucks, such as the MAN eTGE, are used by courier services to transport parcels and packages within cities. Meanwhile, battery electric city buses provide public transportation for local inhabitants and tourists. These vehicles do not travel as far as delivery trucks, do not have to charge throughout the day, and can be charged overnight at cost-effective off-peak rates upon their return to the bus station.

The battery capacities of these vehicles must be able to provide sufficient range for daily routes while also accommodating frequent recharging or opportunity charging. However, ultra-long ranges are not essential, so the battery sizes of these vehicles can be optimized for lower weights and costs. This provides customers with the freedom to choose battery sizes in line with the way they use their respective vehicles.

A modular battery setup is the right solution for all TRATON GROUP brands

With a need to address the environmental and mechanical demands of both long-haul and distribution BEVs, while adhering to specific regional requirements and complying with a patchwork of standards that vary worldwide, one vital component has emerged to meet this challenge: adaptable battery designs. Adaptable batteries can be tailored to suit the specific energy requirements and weight limitations of each vehicle type, optimizing range and performance characteristics.

In his role as Head of Technology Strategy & Innovation in the TRATON GROUP, Dr. Götz von Esebeck is convinced adaptable battery technology in a modular platform provides commercial vehicle manufacturers with the flexibility to create vehicles that can be sold in multiple markets. “For our customers, a commercial vehicle is an investment that only pays off when it is in use and running. This is why we need to make sure that our batteries can meet these demands, while also ensuring that we are prepared for market disruptions and local supply shortages. If our battery technology is standardized in the future, it will be easier for us to respond to market disruptions.”

“For our customers, a commercial vehicle is an investment that only pays off when it is in use and running. This is why we need to make sure that our batteries can meet these demands, while also ensuring that we are prepared for market disruptions and local supply shortages.”

Dr. Götz von Esebeck, Head of Technology Strategy & Innovation in the TRATON GROUP

Developing and testing new battery technologies can be expensive and time-consuming. Adaptable battery designs provide a platform that can be reused across different vehicle models, reducing overall research and development costs.

Overseeing a diverse product portfolio, the TRATON GROUP is working to produce common batteries that can be used worldwide across its brands and vehicles. This was born out of the Company’s development of a Group-wide TRATON Modular System, which provides standardized interfaces for the most important technology areas.

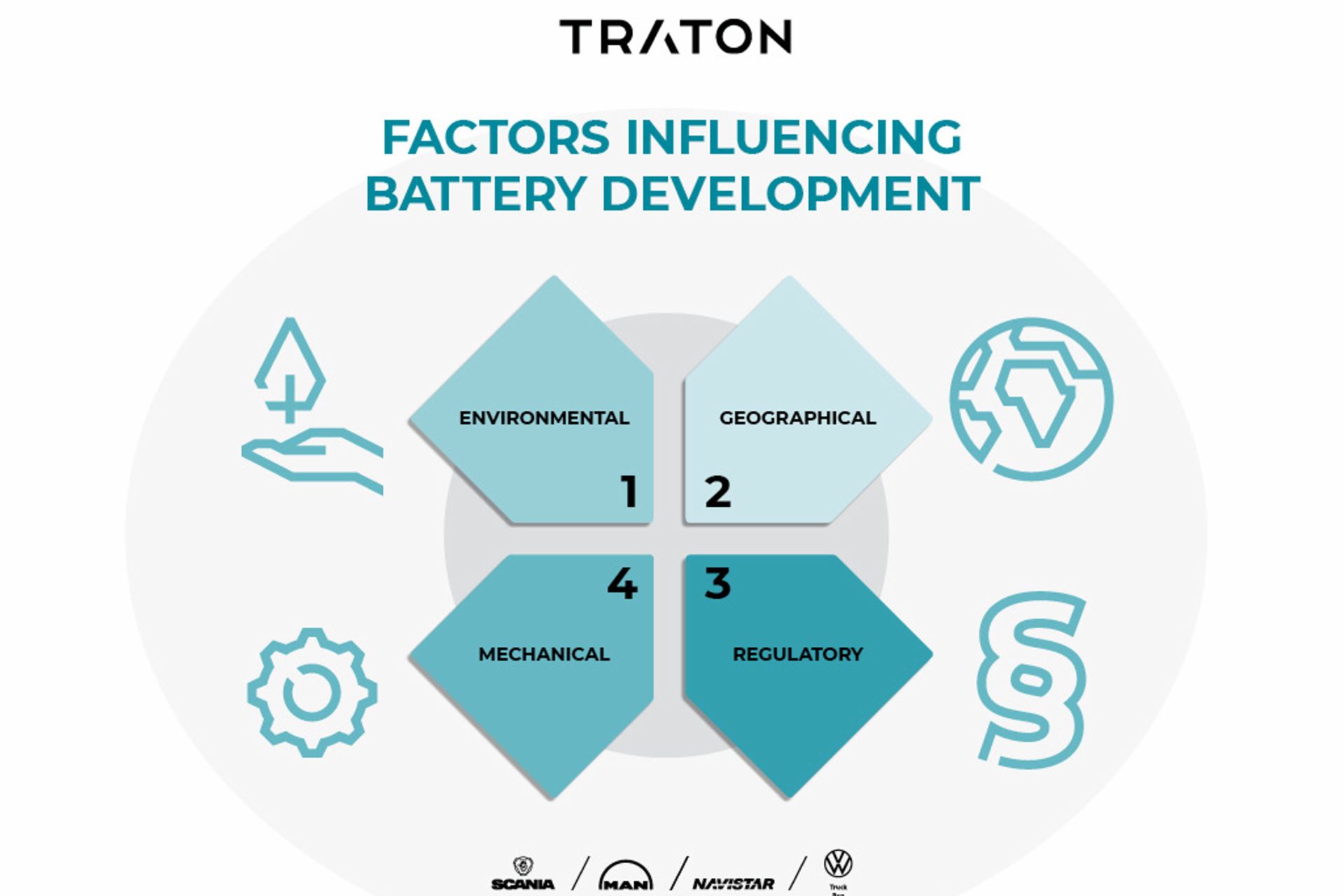

To establish the basic specifications for common batteries and components such as cells and modules, TRATON conducts a comprehensive global use case analysis for commercial BEVs across the globe. In addition to local regulations and supply chain factors, this approach considers both environmental and mechanical factors. For instance, different climate and thermal conditions must be taken into consideration, depending on the place of use. In Sweden, for example, batteries need to be able to operate reliably at extremely low temperatures, which can reduce battery efficiency and range. By contrast, in warmer countries such as Spain, batteries must cope with higher temperatures, as excessive heat can accelerate their degradation.

The impact of extreme environments can be efficiently managed by advanced cooling and heating systems. These systems ensure optimal performance and durability, as well during frequent recharging cycles for distribution vehicles as for long-haul trucks, where the batteries must ensure stable operating temperatures over long distances to maintain health and deliver optimal performance.

Mechanical factors such as shocks and vibrations must also be assessed. In South America, rugged battery packs are essential for rough terrains. Uneven road surfaces can expose vehicles to continuous dynamic forces that can compromise battery and suspension systems. It is crucial that robust suspension systems equipped with vibration isolation techniques and component reinforcement are employed, along with advanced testing procedures, to safeguard batteries from detrimental effects and ensure their reliability, longevity, and overall operational efficiency.

Each market is also subject to region-specific conditions, such as market-specific connectors, which need to be considered when designing trucks to ensure seamless compatibility and efficient operations across diverse territories.

TRATON’s joint battery solution enables synergies and scalability

As Product Manager for Batteries in the TRATON GROUP, Dr. Stefan Tillmann sees first-hand how the Company’s joint solution with its modular system enables synergies and scalability. “At TRATON, we design components that can be used universally across all our brands and applications on a global scale. This strategic approach not only streamlines development, testing, release, and aftermarket support for us as a group, but also increases our resilience to market disruptions. In addition, the use of common components means a reduction in total cost of ownership for our customers.”

“At TRATON, we design components that can be used universally across all our brands and applications on a global scale. This strategic approach not only streamlines development, testing, release, and aftermarket support for us as a group, but also increases our resilience to market disruptions.”

Dr. Stefan Tillmann, Product Manager Batteries in the TRATON GROUP