With a view to a common approach, TRATON has identified three Group-wide joint impact areas: Decarbonization, Circularity, and Human Rights.

- Decarbonization: reduce greenhouse gas emissions across the value chain in line with 1.5°C

- Circularity: decouple the use of resources from our business growth

- Human rights: respect Human Rights and enable a just transition

With this commitment, the TRATON GROUP is also following in the tradition of Earth Day, which draws global attention to the importance of protecting the earth every year on 22 April.

Decarbonization

The TRATON GROUP is committed to doing its part to reduce greenhouse gas emissions throughout its value chain in line with the 1.5-degree target of the Paris Climate Agreement.

Around one-fifth of global greenhouse gas emissions derive from transport. While road freight transport is part of the problem, at the same time, it is the lifeblood of trade and the economy. The most important lever for TRATON to contribute to the fight against climate change is the electrification of its product portfolio. As part of its corporate strategy, TRATON has set itself the goal that around half of its annual new sales in Europe and North America will be zero-emission vehicles (ZEVs) by 2030.

The Science Based Targets initiative

The Science Based Targets initiative (SBTi) is a collaboration between the CDP (formerly the Carbon Disclosure Project), the United Nations Global Compact, World Resources Institute (WRI), and the World Wide Fund for Nature (WWF). It aims to gain support from the business community in reducing emissions in line with the Paris Agreement.

The SBTi supports companies in setting decarbonization targets aligned with climate science through guidance, verification, and approval of the targets submitted by the companies.

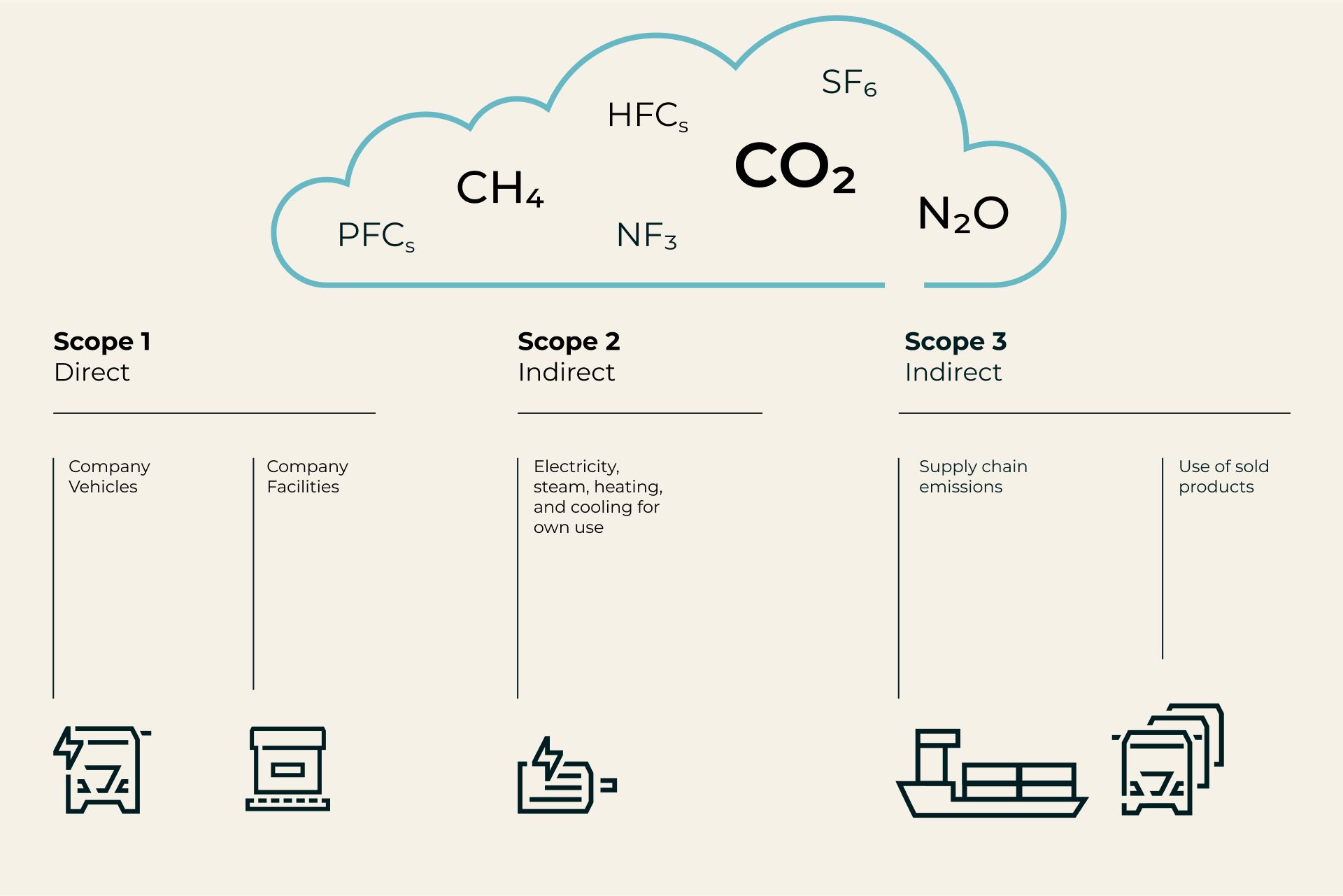

Since its foundation in 2015, 7,922 companies have joined the initiative, more than half of which have set themselves specific targets. Companies setting the targets need to quantify their value chain greenhouse gas emissions across three categories.

How TRATON GROUP brands are decarbonizing

Scope 3 is crucial for TRATON and its Scania, MAN, Navistar, and Volkswagen Truck & Bus (VWTB) brands, as almost all the emissions are generated during the use phase of the lifecycle of vehicles and power solutions. The most impactful decarbonization lever for TRATON is undoubtedly the electrification of its product. Management consultants, Deloitte, recently investigated the relationship between sustainability and innovation and found that companies that are leaders in the field of sustainability are 400% more likely to be considered ‘innovation leaders’ than their competitors.

Scania’s decarbonization targets, which were approved by the SBTi in 2020, includes an aim to reduce greenhouse gas emissions from its production by 50% by 2025. The company also aims to reduce in-use vehicle emissions by 20% during the same period.

The decarbonization targets submitted by MAN at the end of 2021 were validated by the SBTi at the end of April 2022. The company aims to reduce its greenhouse gas emissions significantly by 2030, and is gradually developing its portfolio further to reduce its overall emissions. After MAN has already become the market leader in the e-bus sector in Europe, the brand will focus on long-distance transport and, as of this year, is starting to produce battery-electric trucks with daily ranges of over 600 kilometers. From 2030, MAN will also produce e-buses and autonomous trucks with a range of up to 1,000 kilometers, and is working to be completely CO2-neutral within its production activities also by this deadline.

In 2023, Navistar committed to develop the near-term science-based target. The company’s IC Bus subsidiary electrified its flagship CE Series in 2021, laying the foundation for climate-friendly bus transportation in the U.S. Navistar is aiming for 50% of all sales to be ZEVs in the U.S. by 2030 and 100% by 2040.

VWTB has also set decarbonization targets and will begin production of an electric bus in Brazil in the second half of 2024 with the e-Volksbus. The company is being consistent with its corporate decarbonization strategy, which was introduced in 2021 with the launch of the e-Delivery, which was considered the starting signal for the electrification of the Brazilian transport sector. Last year, VWTB set itself the goal of reducing emissions from its own production and other activities.

“Our brands all share an ambitious commitment and know that net-zero transformation is not only good for the environment; it provides an opportunity to create value for our customers and capture new business opportunities and revenue streams. We need to continue the momentum of Earth Day in our working lives as a matter of course. We want every day at TRATON to be Earth Day in the future!” says Karol Gobczyński, Global Head of Climate & Circular at TRATON.

How the TRATON GROUP supports circularity

In a world in which resource scarcity and environmental pollution are becoming increasingly problematic, the concept of the circular economy is coming more into focus. The transport industry has a special role to play here through measures such as integrating circularity into product designs, using recycled materials, and offering circular services such as remanufacturing.

The TRATON GROUP is integrating a circular mindset from the design phase right until the end of life of its brands’ vehicles. Embracing circular economy principles not only delivers environmental benefits, but also opens up economic opportunities.

“We work on integrating the circularity into the design of our products and scaling up services like remanufacturing. Circularity can and will be a significant source of profit and revenues for companies. We recognize that this is a systemic change that requires collaboration within TRATON, as well as with our existing and new suppliers, partners, and customers. We cannot forget about the role of governments, as regulations are crucial to removing the barriers to scaling up circular economy,” says Gobczyński.

Conserving materials through recycling and remanufacturing

When it comes to batteries, closing the material cycle through recycling saves valuable resources. It also helps to decouple the use of resources from our business growth, while also enabling to avoid greenhouse gas emissions in the supply chain. Designing batteries for recycling is part of circular design principles and allows for materials to be recovered at the end of their lifecycle. But ahead of this, batteries can be reused again and create much higher value for the battery owner and environment: up to 85% of the traction batteries used by TRATON and its brands can be easily reused after an overhaul.

In addition to recycling batteries for e-trucks, Scania is committed to conserving resources when it comes to classic combustion engines. The company sells the market’s largest range of engines that can run on fossil fuels alternatives, such as biodiesel or liquefied biogas. This is an important bridging technology that can be used as a sustainable alternative wherever battery electric vehicles cannot yet be used.

Historically, transportation companies treated the remanufacturing of components and assemblies as an afterthought. The TRATON GROUP now proposes a strategic shift, whereby remanufacturing considerations are built into the design phase from the outset so that materials are proactively optimized throughout the product lifecycle in a sustainable way.

The TRATON GROUP’s Human Rights joint impact area

As a company with an international footprint, the TRATON GROUP’s business operations impact the lives of people every day, within and outside of the Group. It understands it has a corporate responsibility to respect human rights. TRATON is working to understand its impact on humans and society across the entire value chain, aiming to ensure that the voices of those affected are heard.

For TRATON, the topic of human rights is truly cross-functional, so the corresponding joint impact area compiles the toolboxes and engages functions throughout the Group. However, every area of TRATON’s business drives the work needed for how the company impacts people. For example, People & Culture supports actions for employees, while Procurement deals with matters concerning the supply chain.

By establishing a joint impact area for human rights, TRATON has can combine the strengths of its Governance, Risk & Compliance (GRC), and Sustainability departments, which will drive the project and support the entire Group in addressing this area.

“Sustainability is always about the full scope of our impact on the planet, people, and society. The social side of sustainability always starts with understanding the human rights impact – this is the most important imperative – that our actions as a company should never harm the fundamental rights of others,” says Lisa Osbäck, who leads on Human Rights and Social Impact in the Sustainability team of the TRATON GROUP.

TRATON’s Human Rights impact area recently conducted a Group-wide review of its impact on human rights across the entire value chain. Its function is to take care of the areas that are affected; mitigating the negatives but also capturing the opportunity to create value for people and society.

The Human Rights joint impact area is also applying its focus towards the concept of a just transition, which was established in the Paris Agreement. This seeks to ensure that the climate transition does not end up being beneficial for some stakeholders, at the expense of others.

The TRATON GROUP recently marked the first anniversary of the TRATON Human Rights Committee (HRC), a company-wide initiative introduced to monitor its efforts and comply with human rights due diligence legislation.

Meanwhile, the TRATON Policy Statement on Human Rights transparently reflects the company’s commitment and describes which activities have already implemented within the Group for the protection of human rights.