The “Rational Heat Motor” patented by the young German engineer Rudolf Diesel on February 23, 1893, is one of the epoch-making inventions of the modern era. It was an explosive idea that led, a few years later, to the merger of the two companies Maschinenfabrik Augsburg and Maschinenbau-Actien-Gesellschaft Nürnberg – better known today as MAN – and the development of the diesel engine.

Even at the first official acceptance test in 1897, the 20-bhp test engine proved to be highly cost-effective, with an efficiency level of 26% that at the time was considered impressive. The high temperature and pressure enabled the fuel-air mixture in the combustion chamber to ignite independently. This represented a significant advantage.

The efficient powertrain technology was to take the world by storm, and continues to provide the power for today’s globalized freight transportation by road, rail, and water. Nevertheless, almost 130 years after it was invented, the diesel engine is on its way out. Just as the diesel itself put an end to the 19th-century steam engine, in the near future, emission-neutral powertrains will mark the end of the burning of fossil fuels. But this does not happen overnight.

Combining energy for an efficient solution

“With a groundbreaking new diesel engine, designed to be used as a bridge technology over the years to come, that will set new standards for the Group’s heavy-duty trucks,” says Michael Cunningham, Head of Conventional Powertrain at TRATON. The route to achieving this was not an easy one, as the American engineer explains: “The new Common Base Engine (CBE) is the product of an intensive process of evolution. The development work began at Scania in 2012, long before TRATON brought all the brands together under one roof. When MAN became involved in 2015, this developed into a joint global project, with contributions also being made by Navistar in the USA and VWCO in Brazil. Many different cultural, industrial, and regulatory hurdles had to be overcome.” A significant number of experts from all TRATON Brands were involved in the development of the global product.

“TRATON is assembling the future: Scania’s new battery plant in Södertälje and MAN’s new multi-tech plant in Nuremberg are leading the way to the transformation of transportation.”

Catharina Modahl Nilsson, CTO TRATON GROUP

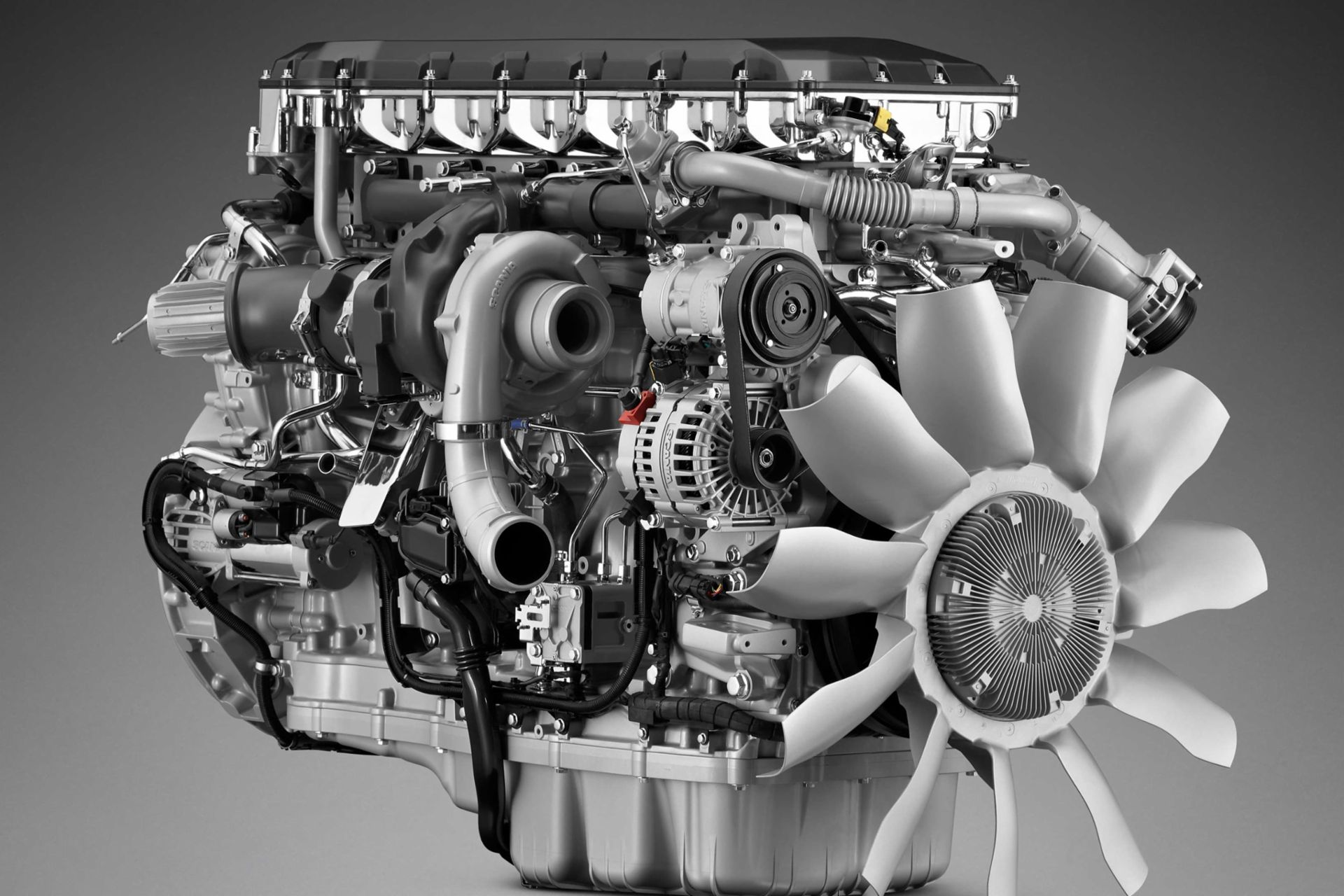

The result of this process is highly impressive. The new 13-liter engine series offers customers significant improvement to fuel efficiency, increased overall efficiency and a significant reduction in CO2 emissions for the TRATON brands.

The Scania 460 R Highline – as the first vehicle powered by the CBE – demonstrated its efficiency as it took first place in Europe’s renowned 1000-point test. With 27.1 liters of diesel per 100 kilometers, the new Scania Super recorded the lowest fuel consumption while maintaining the highest average speed of 84.6 km/h. Michael Kern, tester and specialist journalist for the Lastauto Omnibus magazine, said the following: ”This was a remarkable debut for the brand new world engine in this challenging practical test, and it has left a strong impression in the 460 hp variant, known as DC13-175.” What’s more, the new powertrain meets the EU’s and USA’s strict emissions regulations.

The highly efficient common powertrain with its new 13-liter diesel motor is planned to be gradually inducted into the premium vehicles of the TRATON GROUP.

Limelight on the transition to e-mobility in logistics

To a certain extent, the CBE represents a sustainable lap of honor for diesel technology at TRATON, because the Group is steadily moving toward electric mobility. Just as gasoline and diesel cars are gradually being ousted by electric models, so too the trucks used in the logistics industry will inevitably follow the same trend. “But the move away from combustion engines in the transportation industry will not happen overnight at the press of a button. Some countries are making faster progress with the charging infrastructure for e-trucks than others,” says Cunningham. In addition, geographic differences need to be taken into account. While electric mobility is likely to grow quickly in some densely populated industrial areas as the infrastructure expands, in developing countries alternative powertrains are coming up against a variety of obstacles. “Our new group engine will put us in a very strong position in all these markets and applications in the years to come. The engine is also particularly efficient and produces low levels of pollutant emissions. It is a global engine that has been developed from a collaboration across three continents. All the brands involved have contributed their expertise, their traditions, and their pride, without losing sight of the industrial logic of the project,” says Cunningham and looks back over the history of the brands: “The TRATON Brands Scania, MAN, and Navistar have more than 300 years of combined diesel experience. The CBE brings together the best of all these worlds. this culture of cooperation will continue and will drive the battery electric transformation at TRATON.”

Synergies with the diesel engine to free up resources for electric powertrains

Will the CBE be TRATON’s final fossil internal combustion engine? Cunningham is clear: “It will be the last diesel engine platform developed completely from scratch. We will adapt it in the future to meet customers’ requirements. But our main focus now is on zero-emission commercial vehicles. The synergies from the use of the group engine will enable us to invest more in alternative electric powertrains.” This is very much in the spirit of Rudolf Diesel, because efficiency was the most important consideration for the pioneer of modern mobility. He would definitely be impressed by the CBE: the new engines have an efficiency level of over 50% and are the most modern diesels on the market.