Autonomous vehicles have got their go-ahead. With the German Act on Autonomous Driving of July 28, 2021, Germany became the first country in the world to enact such a law. This regulates and essentially permits the use of autonomous vehicles in defined operational areas, such as traffic between logistics terminals. In this way, the lawmakers want to enable practical trials of this technology not only on secured premises, but also on public roads, subject to human supervision.

In recent years, driver assistance systems such as emergency brake assist (EBA), GPS-controlled cruise control, or the turn-off assistant for trucks have proven that technology, and computer-controlled technology in particular, not only makes vehicle operation more comfortable, but also safer and more economical. Nevertheless, experts estimate that 94 percent of all traffic accidents today are still due to human error. Less damage, fewer injuries, and fewer deaths on the roads would be reasons enough to push ahead with the development of autonomous vehicles.

Maximum advantages in freight mobility

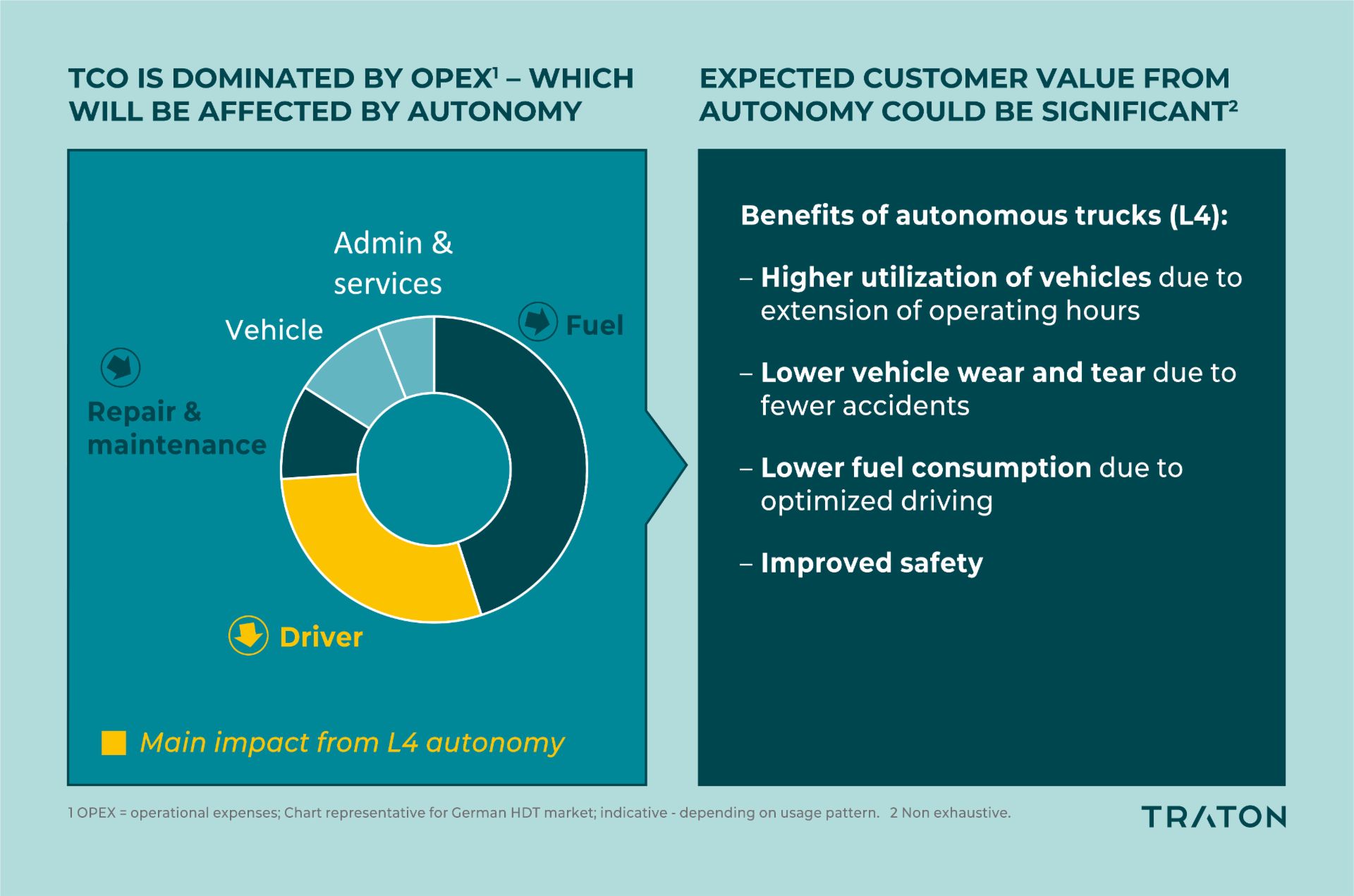

In freight transportation, however, economic and ecological arguments weigh almost as heavily. Self-driving trucks can cover longer distances without taking a break and reduce the high personnel costs, which after fuel costs account for the largest proportion of the total operating costs of a truck. Furthermore, they do not require long rest periods, provide an improved sense of security, and thus increase efficiency. At the same time, less damage also means fewer breakdowns and lower repair costs. In addition, automated driving leads to lower fuel consumption and thus reduces the impact on the environment. A study by the researchers at the University of Michigan, for example, puts this potential at up to nine percent for Level 4 vehicles. And last but not least, autonomous trucks represent a solution to two of the biggest challenges facing the transportation industry: the massive increase in driver shortages. The growing demand for transport services is already being offset by an increasing shortage of professional drivers. According to the German Road Haulage, Logistics, and Disposal Association (Bundesverband Güterkraftverkehr Logistik und Entsorgung), around 30,000 truck drivers retire each year in Germany alone, while only 17,000 newcomers join the ranks.

These are reasons enough for the international commercial vehicle company TRATON, with its brands Scania, MAN, Volkswagen Caminhões e Ônibus (VWCO), and Navistar, to put the development of autonomous vehicles at the top of its agenda. TRATON agreed on a joint global strategy across all Group brands to develop solutions for autonomous driving. “We are currently testing the technology of autonomous trucks. By focusing on the most promising results and solutions, we want to accelerate development to the point where we can realize autonomous driving trucks as series solutions, which we expect to be by 2030,” says Catharina Modahl Nilsson, TRATON’s Chief Technical Officer.

Just a few years until series production is ready from 2030? It sounds ambitious — and it is. But autonomous driving projects are not new to the brands of the TRATON GROUP. Testing trucks have been used for several years, and their development continues, so that these vehicles are ready for customers.

Practical testing around the world

In 2018, Scania began testing self-driving trucks in a salt mine belonging to the Australian mining group Rio Tinto. The decision to test autonomous vehicles in a mine, of all places, away from any road traffic, was made for good reason, as Björn Winblad, Head of Scania Mining, explains: “Mining sites are ideal for testing new autonomous technologies because of their high vehicle utilization. At the same time, the safety and productivity advantages of automation are of great benefit to mine operators.” In addition, the tasks that an autonomous truck has to handle here are less complex than, for example, in urban traffic.

Scania even went one step further with another project. While in the Australian mine a safety driver on board the vehicle monitors every action of the autonomous control system and can intervene if necessary, the dump truck concept vehicle called Scania AXL, presented in 2019, not only dispenses with a driver, but consequently dispenses with a cab altogether. The use of the autonomous dump truck on cordoned-off terrain is expected to provide additional insights for the future readiness of so-called Level 5 vehicles for series production, the highest construction stage of autonomous vehicles.

Hamburg Truck Pilot successfully completed

Development engineers are finding suitable application profiles for testing autonomous trucks not only in mining, but also in container terminals. Long daily operating times and frequently recurring driving and maneuvering also make it possible here to collect a large amount of data in a relatively short time — a prerequisite for the development of safe and reliable self-driving systems. So it’s no coincidence that TRATON subsidiary MAN joined forces with Hamburger Hafen und Logistik AG to launch the Hamburg Truck Pilot project in 2018. Here, the project partners are testing the use of autonomous trucks at Altenwerder container terminal and their integration into the highly automated handling processes. After months of preparations, the practical test took place in May 2021. The truck moved fully autonomously within the port area under the constant supervision of a safety driver — from navigating to the assigned loading block to maneuvering into the final loading position.

The follow-up project goes one step further: with the ANITA (German acronym that translates as Autonomous Innovation in Scheduling) automation project at the DUSS container handling terminal near Ulm and the neighboring container depot of DB Intermodal Services GmbH, MAN, Deutsche Bahn, and the Fresenius University of Applied Sciences are jointly developing solutions that will enable automated transports in so-called hub-to-hub traffic in the future.

Hub-to-hub transport in the focus of automation and the current test phase

And it is precisely here — in regular transport between two logistics centers or hubs — that TRATON CTO Catharina Modahl Nilsson sees the greatest potential for implementing autonomous solutions in the short term, which are expected to be in series production by 2030. “Hub-to-hub traffic largely runs along highways. Compared to inner-city traffic, trucks here are exposed to relatively little situational complexity. At the same time, given the intensive use and working conditions, the driver shortage as well as the personnel costs of the driver are particularly significant here.Hub-to-hub transportation could therefore be the first mode of transportation where self-driving trucks become a reality on public roads.”

So it’s no surprise that TRATON is the first truck manufacturer in Europe to test autonomous transport between two hubs on public roads. Over a distance of around 300 kilometers, two autonomous test trucks shuttle in regular delivery operations along the Swedish E4 highway between the Scania plants in Södertälje and Jönköping. Always on board: a safety driver and a test engineer from project partner TuSimple, an American start-up specializing in control systems for self-driving trucks. The hub-to-hub project in Sweden is not the first time TRATON and TuSimple have worked together. In the US, TRATON subsidiary Navistar has long had a development partnership with TuSimple, which has already seen 50 Navistar test trucks complete several million kilometers in self-driving mode on American interstates.

Now it won’t be long before the first self-driving trucks begin test operations on German highways as well — after all, 2030 is not far off.