Transmetrics, a logistics technology provider specializing in Business Intelligence, automation, and optimization, has been using machine learning and predictive analytics to optimize transport planning for over ten years. Recently, they have noticed a shift in the behavior of both carriers and shippers. To address this, it's essential to synchronize data from different sources, create a digital toolkit, and enable visibility and predictability.

We spoke to Dimitar Pavlov, the Chief Growth Officer at Transmetrics who led an insightful workshop with the TRATON team, about the advantages of such a digital toolkit and how logistics operators can profit from it.

What characterizes the digital tools of a successful logistics company today?

Logistic operators have realized that working in several fragmented and decentralized systems like Excel for complex planning is no longer fit for purpose. Forward-thinking logistics companies are now experimenting with cutting-edge digital tools that allow them to streamline their business and gain a competitive advantage for years to come. Digitalization refers to the process by which data from throughout the entire transportation ecosystem is processed through advanced digital technologies, leading to fundamental changes in business processes that can result in new business models. Today's best performing logistics companies started investing in digitalization a long time ago, placing themselves ahead of the curve.

What problems can detached data cause?

Poor data quality and limited technical know-how can lead to difficulties in managing operations and costs. Traditional methods of collecting and analyzing data in Excel spreadsheets are time-consuming and reactive and don’t reflect today’s dynamic market demands. Logistics data sets require careful context-based analysis, including specific factors like trade routes, vehicle models, fuel efficiency, and cargo properties. Such precise assessments provide insightful guidance for decision-making. Forward-thinking logistics leaders are now distinguished by their ability to utilize digital tools, eliminate operational obstacles, and use data analytics to their advantage. By adapting to changing industry and customer needs, they turn data into insights.

Artificial intelligence and big data analysis are discussed in almost all industrial sectors. What are the potential use cases for AI in the logistics and transport sector?

First, let's look at the growth estimates for artificial intelligence in the logistics market. While some logistics companies are already using AI, this trend is rapidly evolving. According to a Straits Research report, AI in the global logistics market was valued at USD 7.96 billion in 2022 and is expected to reach USD 238.89 billion by 2031, reflecting a CAGR of 45.93% during the same period (2023-2031). As per these statistics, integrating artificial intelligence is becoming increasingly important to address the challenges faced by the logistics industry. AI can increase the efficiency of decision-making processes for companies that incorporate it into their strategies. However, many businesses need help implementing clear and reliable data feeds to avoid data gaps, duplications, and entry errors that hamper operational and financial visibility.

What data can AI work with? How can this tool be used?

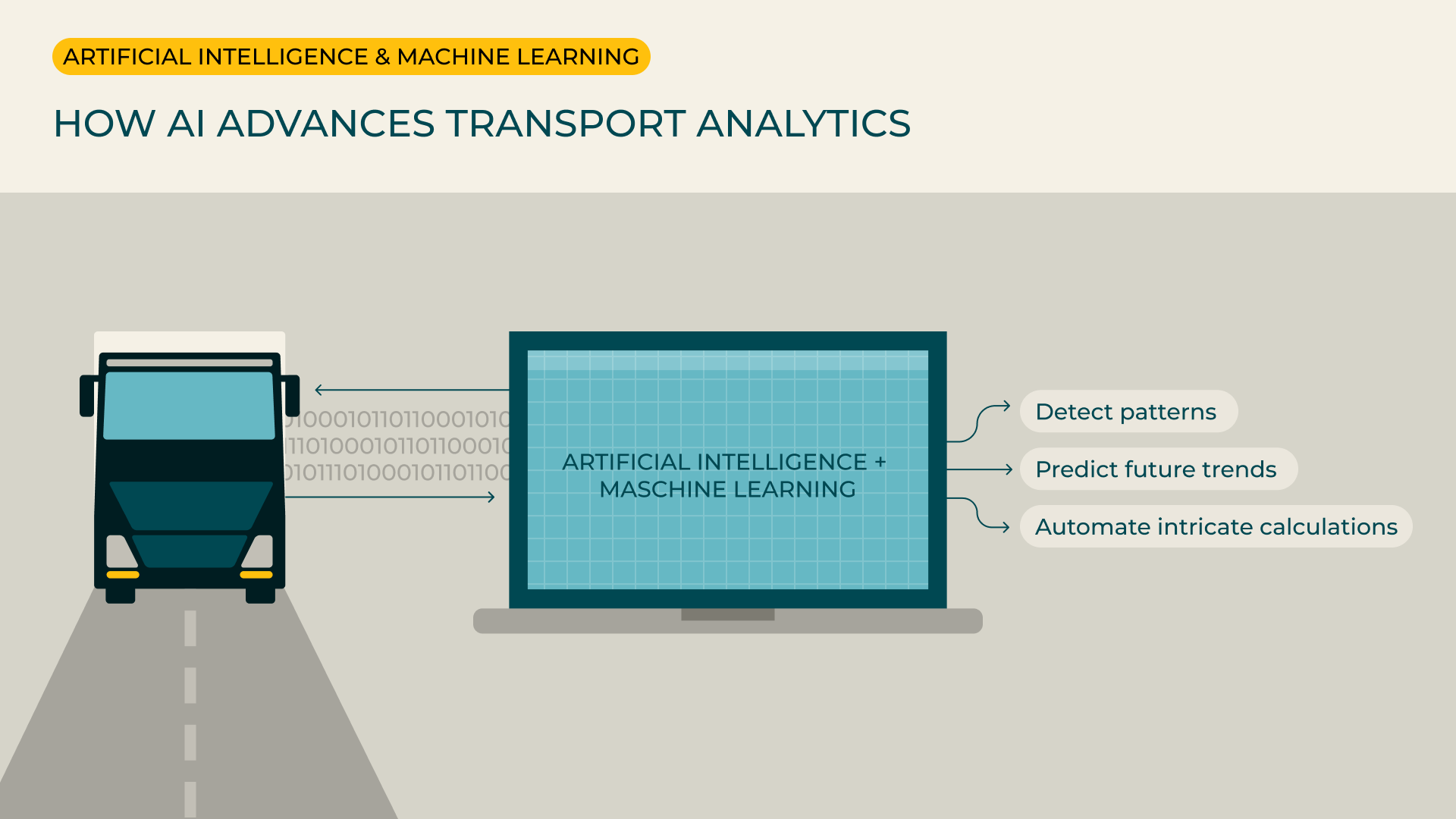

Machine-learning algorithms can help improve data accuracy and reliability by filling gaps and removing errors and duplicates. AI-driven big data analytics can extract valuable insights by analyzing large volumes of data, detecting patterns, predicting future trends, and automating time-consuming calculations. Enterprises can leverage AI's capabilities to plan effectively, utilize resources efficiently, and allocate resources optimally for sustainable operations. Data quality for AI is as important as fleet reliability for logistics value chains.

“Data quality for AI is as important as fleet reliability for logistics value chains.”

Dimitar Pavlov Chief Growth Officer at Transmetrics

What could be the impact of AI and advanced data analysis on this industry?

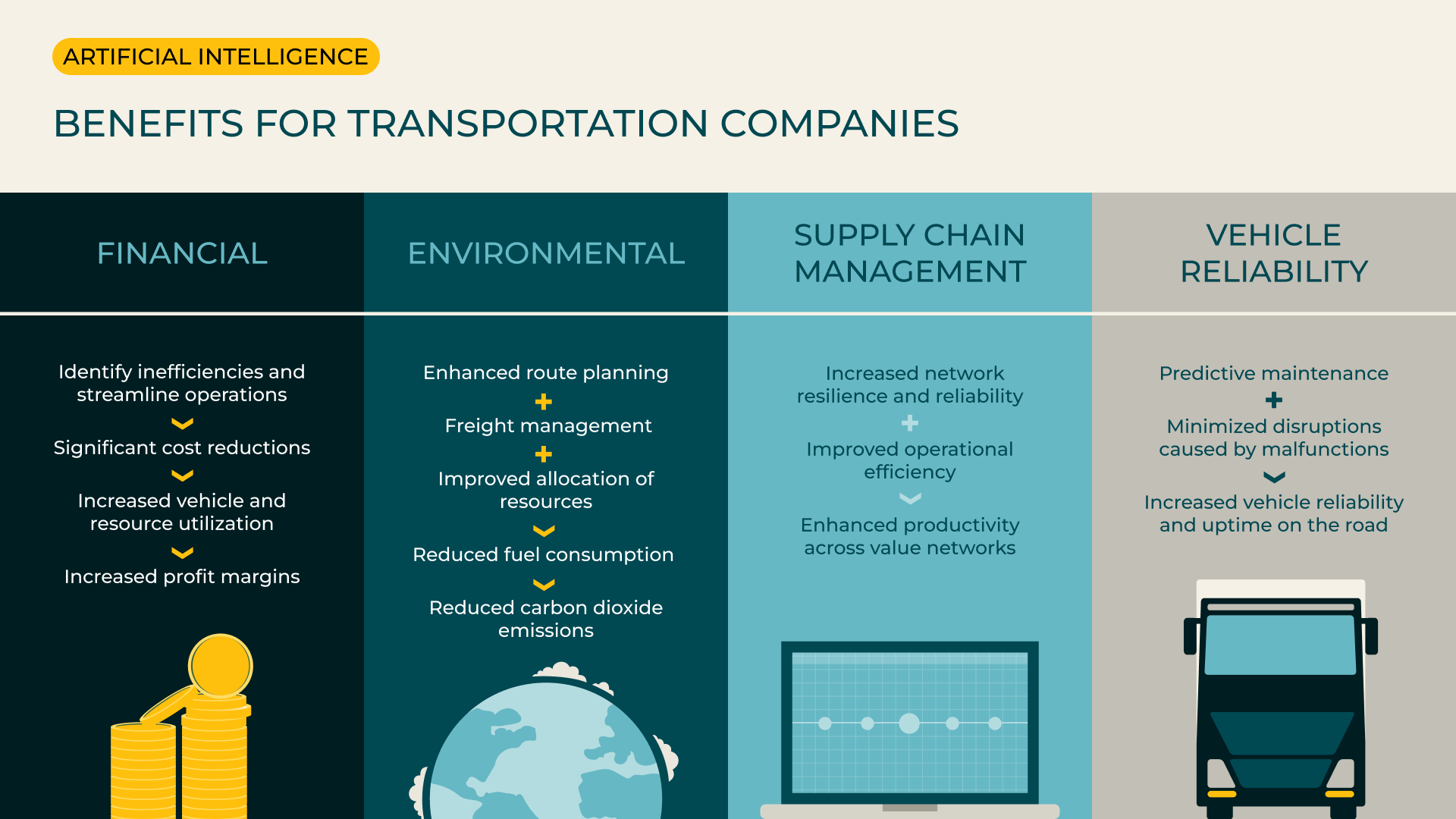

Advanced data analytics and artificial intelligence have the potential to revolutionize the logistics industry by analyzing data sets, identifying inefficiencies, and streamlining operations to increase profit through remarkable cost reductions and increased vehicle utilization. These tools can also protect the environment by enhancing route planning and freight management, improving resource allocation, and reducing fuel consumption and carbon dioxide emissions. In addition, AI can increase network resilience and reliability, improve operational efficiency, and enhance productivity across value networks. The application of digital twin technology, for example, provides organizations with virtual replicas of their commercial vehicles and entire logistics systems, which allows them to prepare and simulate different scenarios and optimize network performance. Predictive maintenance based on insights gained through data analytics and artificial intelligence can also increase vehicle reliability and uptime on the road while minimizing disruptions caused by malfunctions, thereby improving overall productivity.

Can you provide an example of how a transportation company has successfully integrated AI into their business model and how it has affected their operations?

We have developed numerous AI-powered applications that help transportation and logistics companies improve operations, reduce costs, and gain a competitive edge. We are automating driver payroll calculations for a European freight transportation company to free up their team and introduce a data-driven, error-proof process into their operations. In this example, we have transformed operations, made work easier, increased efficiency, and created a competitive advantage in the transportation industry.

AI can improve data quality and enable advanced analysis to extract valuable insights – for example, accurately calculating order profitability and building various aggregations at multiple levels (vehicle, customer, trade lane, etc.), automating the entire reporting process, analyzing trends, and implementing data-driven decisions. It can also minimize the spreadsheet’s role in analysis and make the industry more attractive to work in.

Can you mention a specific example of how manual work is eliminated by smart solutions?

Some payroll calculations are performed in-house by a team of over 30 people. Every time hundreds of drivers have to collectively return home around the holidays (e.g., Easter, Christmas, August, etc.), this task becomes an immense pain for the company. It is prone to human error simply because of the sheer volume of work. To tackle this, we have developed a plan for the next vacation season. We aim to automate these payroll calculations right away, in a centralized system. This will increase the efficiency of the entire team, eliminate errors, free up capacity for higher value-added activities, and create a competitive advantage.

What is the role of commercial vehicle manufacturers in the transportation chain, and how will it change in the future?

Manufacturers can play a vital role in the future transportation ecosystem by going beyond their traditional role and providing advanced, integrated solutions for the logistics and transportation sectors. They're already developing vehicles with smart technology, interconnected services, and analysis systems to improve performance, facilitate predictive maintenance capabilities, and optimize transport routes. In the future, they’ll adopt sustainable practices, and explore autonomous technologies.

“Manufacturers can play a vital role in the future transportation ecosystem by going beyond their traditional role and providing advanced, integrated solutions for the logistics and transportation sectors.”

Dimitar Pavlov Chief Growth Officer at Transmetrics

What will the relationship be between commercial vehicle makers and digital service providers?

Logistics companies would prefer a one-size-fits-all solution, but currently, manufacturers and tech providers can only offer a portion of the services needed. Combining the efforts of vehicle makers and digital service providers is the solution. Digital service companies and vehicle manufacturers aim to create sustainable partnerships to provide comprehensive logistics solutions. This will result in the seamless convergence of physical vehicles and digital services.

Manufacturers will integrate technical features into their vehicles. At the same time, digital companies’ software and platforms will optimize logistics operations using truck data in combination with data from trailers, cargo or goods, and any machines or vessels that interact in customer value networks. This integration means end-to-end solutions combining premium vehicles with digital tools from a single supplier or through partnerships. Such partnerships could lead to innovations in real-time tracking, predictive maintenance, optimized routing, and more, all tailored to carriers' specific needs.

About Transmetrics

Transmetrics optimizes transport planning by leveraging the power of machine learning and predictive analytics. It combines the strengths of humans and artificial intelligence to ensure the highest operational benefits and reduce the environmental impact of logistics.